Ultra-High Purity Nitrogen Production: Controlling CO Impurities at the ppb Level

In cutting-edge fields like semiconductor manufacturing and optoelectronic packaging, ultra-high purity nitrogen (≥99.9999%) requires CO impurities to be strictly controlled ≤0.1 ppm—a challenge not just of gas purity, but of end-to-end process optimization.

1. Key Sources of CO

1) Air Feedstock Background: While cryogenic air separation can purify nitrogen, the natural 0.1–0.5 ppm CO in air is difficult to fully remove.

2) Hydrocarbon Conversion Byproducts: Incomplete combustion of hydrocarbons (e.g., CH₄) in high-temperature equipment generates CO.

System Contamination: Organic impurities from compressor lubricants or sealing materials, thermally decomposed at high temperatures, further oxidize into CO.

2. Core Purification Process: The "Combo" of Catalytic Oxidation + Multi-Stage Adsorption

Step 1: Catalytic Oxidation

Precious/transition metal catalysts (e.g., Pt/Pd-Al₂O₃) efficiently convert CO to CO₂ while consuming trace O₂ (dynamic O₂ balance control is critical).

Step 2: Synergistic CO₂ Removal

A 13X molecular sieve adsorption tower simultaneously dehydrates (dew point ≤-80°C) and reduces CO₂ to ≤0.1 ppm—a prerequisite for subsequent residual CO purification.

Step 3: Residual CO Precision Control

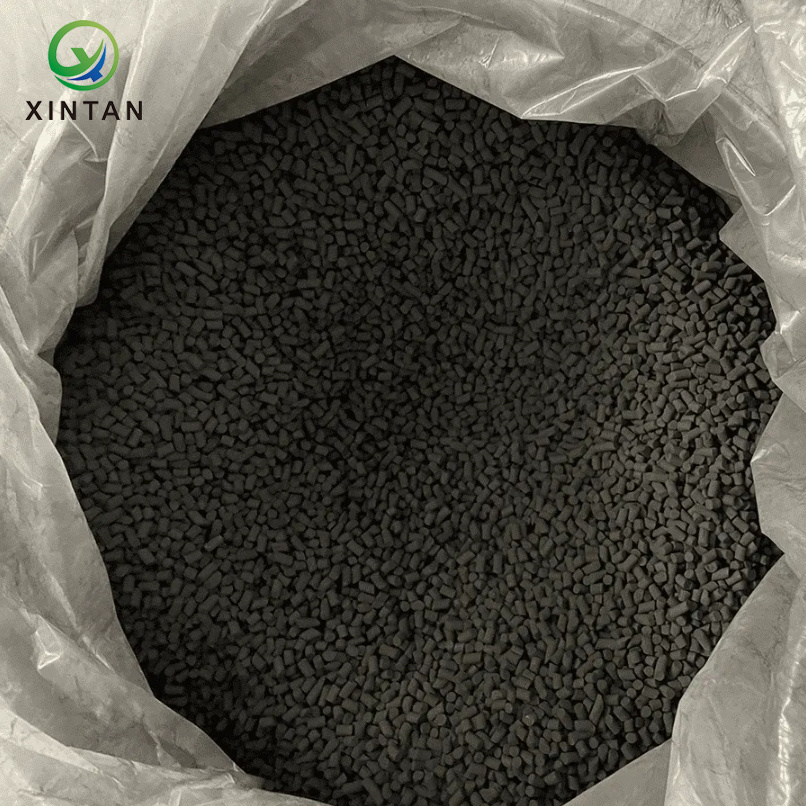

A CuY molecular sieve adsorption tower (selective for CO) further reduces CO to <0.01 ppm, meeting the most stringent electronic-grade gas standards.

Critical Process Control Principles

Catalyst Poisoning Prevention: Feed gas must be pre-treated to remove H₂S, HCl, and other poisons, with periodic high-temperature regeneration (carbon removal) to restore activity.

Adsorbent Regeneration Cycles: TSA (Temperature Swing Adsorption) or PSA (Pressure Swing Adsorption) cycles are tailored based on gas volume/impurity load (typically every 8–24 hours).

Oxygen-Free Environment: Post-catalytic oxidation, O₂ must be limited to ≤0.1 ppm to prevent reactions with downstream adsorbents or product contamination.

Related News