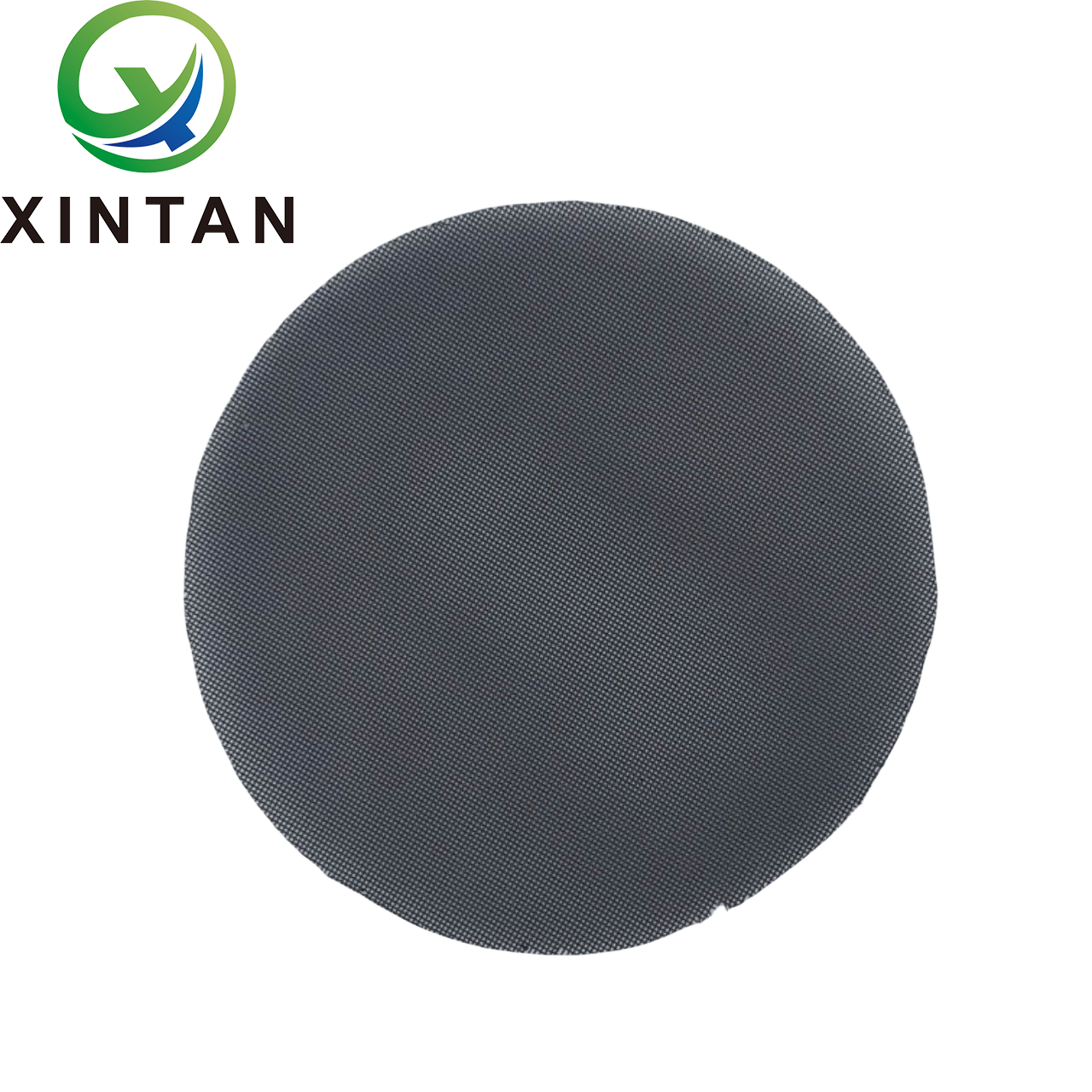

Ozone removal filter(Copper mesh carrier)

Model: XT-CAT-07Cu

Uses: ozone decomposition in lab

Shape: Mesh,Φ 5CM or customize

Composition: Copper mesh coated with CuO and MnO2

Characteristic: light weight, low wind resistance;

Index: See product details for specific parameters

Package: Carton

Application area: used for ozone removal and decomposition of precision electronic equipment, and can also be used for ozone analysis equipment to produce zero gas (standard gas).

Product Details

1)Product introduction

The ozone removal filter(Copper mesh carrier) developed by Hunan Xintan is an efficient ozone decomposition catalyst supported by copper wire mesh, which can decompose ozone into oxygen at room temperature. The appearance of ozone removal filter is black mesh, with the filter of 40 mesh /60 mesh /80 mesh /100 mesh or customized, the conventional size is a circular diameter of 5cm, other sizes can be customized according to user requirements. The product has the characteristics of light weight, high efficiency, low wind resistance, safe and no energy consumption, etc. It is mainly used for ozone removal and decomposition of precision electronic equipment, and can also be used for ozone analysis equipment to produce zero gas (standard gas).

2)Parameters

|

Appearance |

Black mesh |

|

Carrier |

Copper mesh, 40 mesh /60 mesh /80 mesh /100 mesh or customized |

|

Active ingredients |

Cu, CuO, MnO2 |

|

Diameter |

5cm or customized |

|

Bulk density |

1.4 g/ ml |

|

Operating temperature |

20~30℃ |

|

Decomposition efficiency |

≥98%, ozone concentration after decomposition is less than 0.01ppm. |

|

Method of application |

Laminated use, generally use 10 to 20 layers |

|

Service life |

1 year |

3)Product advantages

A)Stable performance and high efficiency. Ozone removal filter(Copper mesh carrier) has high active ingredient content, stable and durable performance.

B)Safe to use. Free of volatile components and combustible components, safe to use, no secondary pollution. Non-dangerous goods, easy to store and transport.

4)Applications

A)Ozone removal and decomposition of precision electronic equipment.

B)Ozone analysis equipment to produce zero gas (standard gas).

5) Remark:

A)Pls avoid water and dust when storing, sealed at room temperature.

B)After a period of use, the activity of the ozone removal filter may be significantly reduced, the filter and desiccant can be taken out, dried in a 100℃ oven for 2 hours, and then re-loaded into the purifier for use.

6)Technical support

Based on working temperature, humidity, O3 concentration, air flow, etc. Xintan team can offer advice on the size and quantity needed for your device.

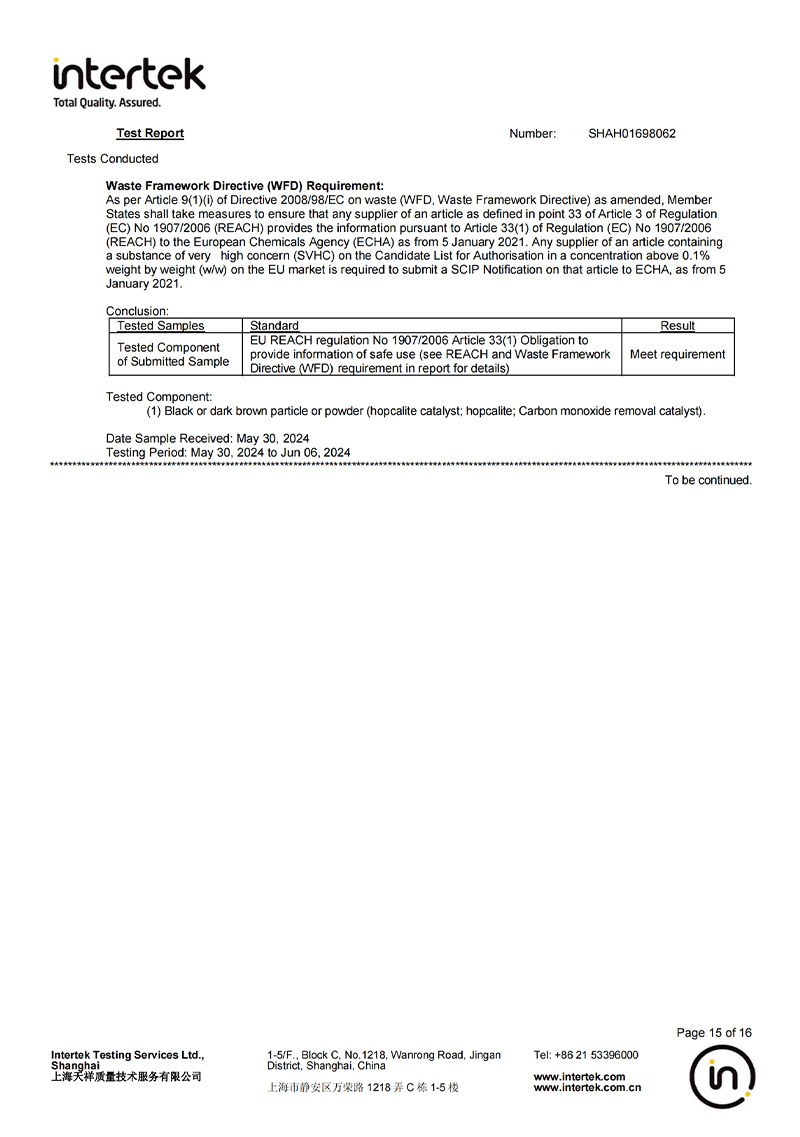

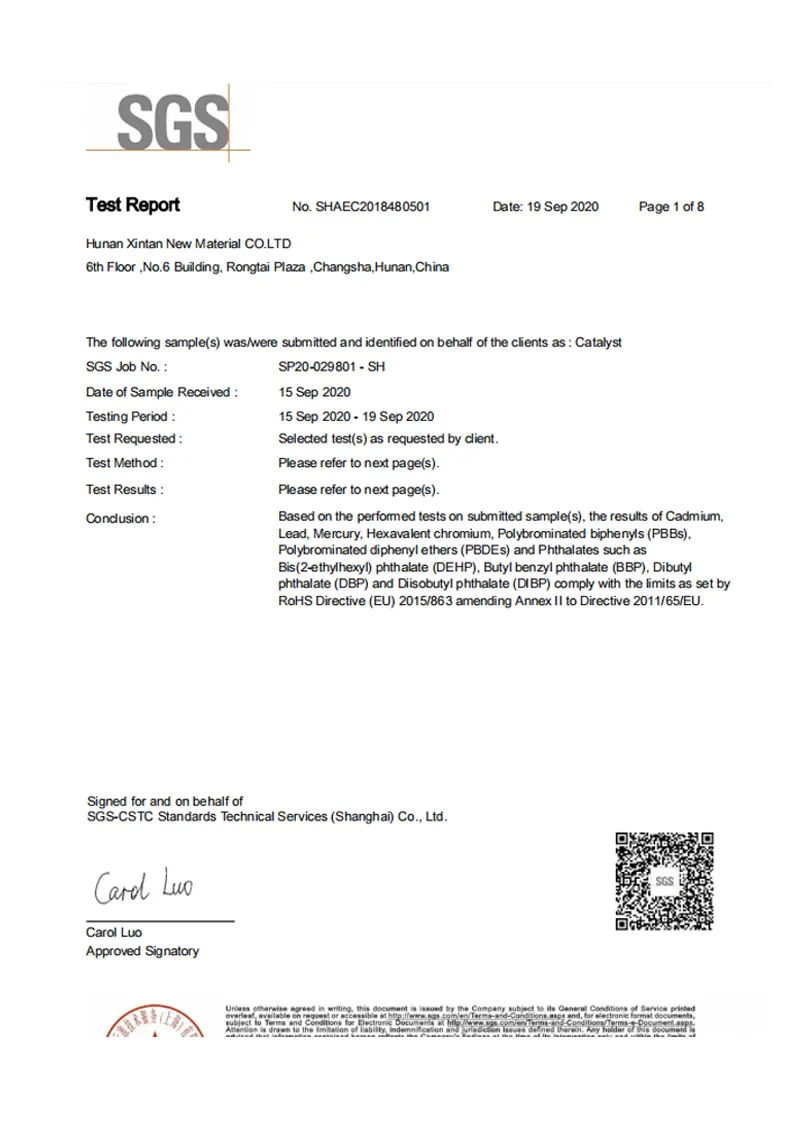

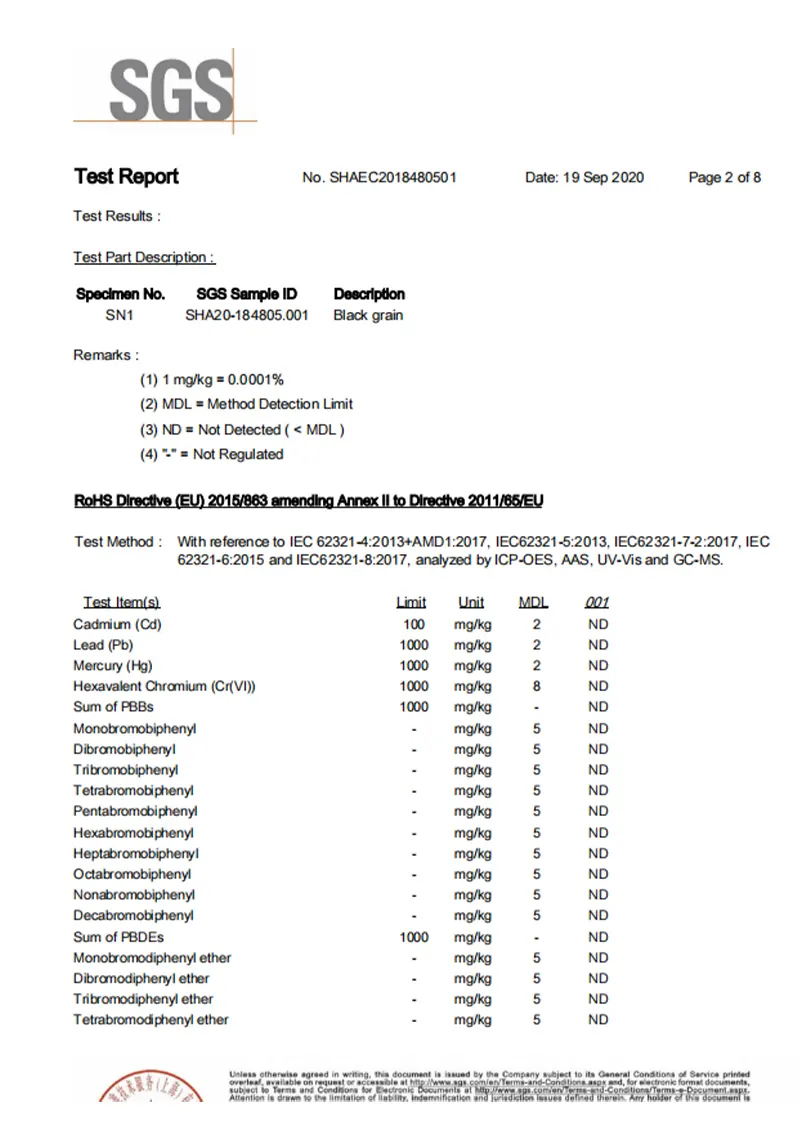

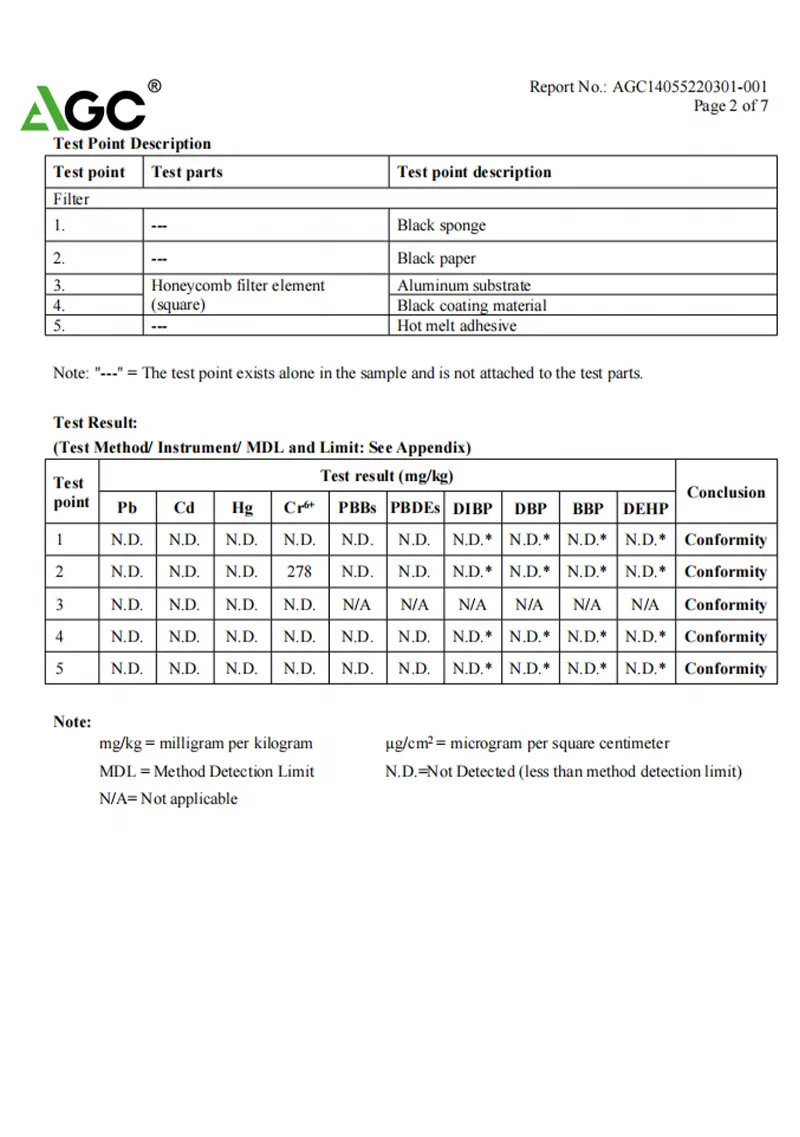

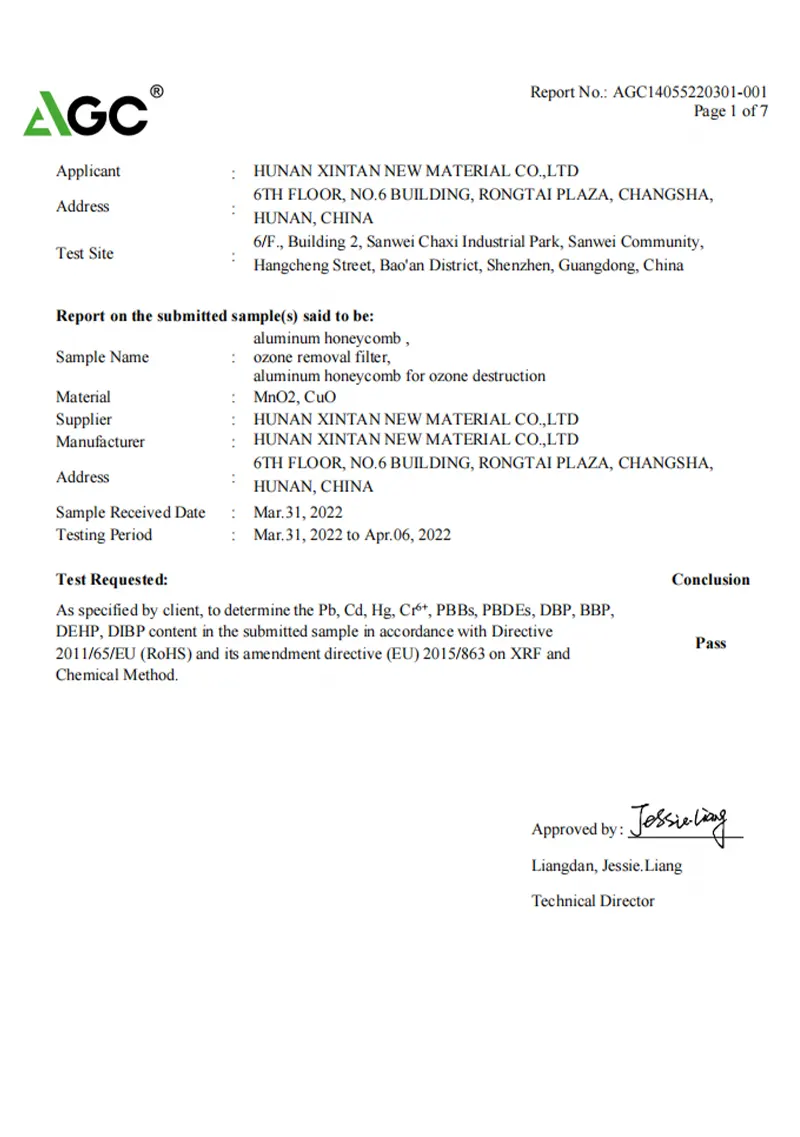

Qualification Certificate

Test Report

Quality Management System Certificate

SGS

SGS

AGC

AGC

Related Products

Carbon molecular sieve, which are composed of elemental carbon, are a new type of adsorbent and an excellent non-polar carbon material. Hunan Xintan carbon molecular sieve is black columnar particles with a diameter of 1.0-1.3mm or customized. The product has the characteristics of strong nitrogen production capacity, high nitrogen recovery rate, long service life and low production cost. Carbon molecular sieve contain a large number of micropores, which have a strong instantaneous affinity for oxygen molecules and can be used to separate O2 and N2 in the air. In industry, carbon molecular sieves are often used in pressure swing adsorption (PSA) nitrogen production, which is suitable for various types of pressure swing adsorption nitrogen generators.

CO removal catalyst (Ceramic honeycomb)

CO removal catalyst (Honeycomb) uses cordierite honeycomb ceramic as a carrier and is a highly active catalyst prepared from a variety of rare earth metals. The CO removal catalyst (Honeycomb) produced by Hunan Xintan has the characteristics of high structural strength, strong surface coating adhesion, and is not easy to fall off. This catalyst can not only be used to treat carbon monoxide in flue gas, but also has high catalytic performance in chlorine-containing working conditions, and can be used for the treatment of chlorine-containing organic waste gas, and is widely used in the treatment ofsteel flue gas, lime kiln flue gas, waste incineration smoke and other smoke.

CO removal catalyst (Pt and Pd)

CO removal catalyst (pellet with Pt and Pd) is a precious metal palladium catalyst with alumina as a carrier. The carbon monoxide precious metal catalyst produced by Hunan Xintan is dark brown spherical particles with a diameter of 3-5mm, which is mainly used to remove H2 and CO at 20℃~300℃. The catalyst can convert CO to CO2 and H2 to H2O. It does not contain MnO2, CuO or S, so it can be safely used for CO purification in CO2. CO removal catalyst (pellet with Pt and Pd) have the characteristics of high catalytic efficiency, stable performance, safety, no energy consumption and long service life, and are widely used in the food industry.

CuO catalyst (for removing oxygen from Nitrogen or Methanol Synthesis)

CuO catalyst (for removing oxygen from Nitrogen or Methanol Synthesis) developed by Hunan Xintan is made of a high proportion of copper oxide (CuO) and inert metal oxides. It is a black cylindrical particle with a diameter of 5mm and a length of 5mm. The catalyst has the characteristics of high active component content, high packing density, low cost and long service life. It is a catalyst used to remove oxygen from nitrogen or inert gases such as helium and argon, which can efficiently convert oxygen to CuO without the need for additional energy. It does not contain any dangerous substances. The catalyst is widely used in gas treatment because of its high efficiency. The catalytic deoxidation reaction equation is as follows: CuO+H2=Cu+H2O 2Cu+O2=2CuO