VOCs treatment catalyst (Pt and Pd )

Model: HNXT-CAT-V01

Uses: removing VOCs

Shape: honeycomb 100*100*50mm or customized

Composition: ceramic honeycomb coated with Pt, Cu, Ce

Characteristic: high catalytic performance; High -efficiency; energy-saving

Index: See product details for specific parameters

Package: Carton

Application area: spraying, printing, glass fiber reinforced plastic, UV coating, pharmaceutical, chemical, petrochemical, enameled wire and so on.

Product Details

1)Product introduction

VOCs treatment catalyst is a yellow honeycomb catalyst made of bimetallic platinum(Pt) and copper(Cu) as active components and cordierite honeycomb ceramic as carrier, the size is 100*100*50mm or can be customized according to customer requirements. VOCs treatment catalyst produced by Hunan Xintan is a special process to add a small amount of rare earth materials, so that the catalyst structure is more stable, the surface active coating adhesion is stronger, not easy to fall off. The catalytic performance is excellent, with good temperature resistance, high purification efficiency, and low ignition temperature. The catalyst is suitable for conventional VOCs gas treatment, the treatment effect of benzene series is better, can be widely used in CO and RCO devices. VOCs treatment catalyst is mainly used in waste gas treatment industry, such as spraying, printing, glass fiber reinforced plastic, UV coating, pharmaceutical, chemical, petrochemical, enameled wire and so on.

2)Parameters

|

Active ingredients |

Pt, Cu, Ce, etc |

|

GHSV(h-1) |

10000~20000(according to actual operatingcondition) |

|

Appearance |

Yellow honeycomb |

|

Dimension(mm) |

100*100*50 or customize |

|

Active load |

Bullion content: 0.4g/L |

|

Operating temperature |

250~500℃ |

|

Maximum short-term temperature resistance |

800℃ |

|

Conversionefficiency |

>95% (Final result according to actual operatingcondition) |

|

Air speed |

<1.5m/s |

|

Bulk density |

540± 50g/L |

|

Carrier |

Cordierite honeycomb, square, 200cpi |

|

Compressive strength |

≥10MPa |

3)Product advantages

A)Excellent catalytic performance. The purification rate of organic waste gas treated by catalytic combustion method is generally over 95%, and the final products are CO2 and H2O, which are harmless and do not have secondary pollution problems. In addition, due to the lower temperature, NOx generation can be greatly reduced.

B)Wide application range. VOCs treatment catalyst is widely used, mainly used in spraying, printing, glass fiber reinforced plastic, UV coating, pharmaceutical, chemical, petrochemical, enamelled wire and other exhaust gas industry. The composition of the printing industry waste gas is relatively simple, the main components are benzene series, esters, alcohols, ketones and so on.

C)No additional heating required. VOCs treatment catalyst acts as a catalyst at lower temperatures, reducing energy consumption in the catalytic combustion process.

4)Applications

VOCs treatment catalyst is mainly used in waste gas treatment industry, such as spraying, printing, glass fiber reinforced plastic, UV coating, pharmaceutical, chemical, petrochemical, enameled wire and so on.

5) Remark:

A)The catalyst should be moisture-proof, Keep in an airtight container, prevent contact with air, so as not to deteriorate.

B)The waste gas shall not contain sulfur, phosphorus, arsenic, lead, mercury, halogens (fluorine, chlorine, bromine, iodine, astatine), heavy metals, resins, high-boiling point, high-viscosity polymers and other toxic chemical elements or substances.

C)In the process of catalytic combustion reaction, sufficient oxygen should be guaranteed to react with VOCs. When oxygen is insufficient, the purification efficiency of waste gas will be directly affected, resulting in carbon black and other by-products attached to the surface of the catalyst, resulting in catalyst inactivation.

D)The catalyst should be handled gently, and the direction of the catalyst hole should be consistent with the direction of the air flow when filling, and placed closely, without gaps.

E)Before entering VOCs gas, it is necessary to enter flowing fresh air to fully preheat the catalyst (preheat to 240℃~350℃, set according to the highest temperature required by the most difficult gas in the exhaust gas component).

F)The optimal operating temperature of the catalyst is 250~500℃, the exhaust gas concentration is 500~4000mg/m3, and GHSV is 10000~20000h-1. It should be avoided as far as possible to avoid the sudden increase of exhaust gas concentration or the long-term high temperature of catalyst above 600℃.

G)At the end of the operation, firstly cut off the VOCs gas source, use fresh air to continue heating for 20 minutes and then shut down the catalytic combustion equipment. Avoiding catalyst in low temperature contact with VOCs gas, can effectively prolong the service life of catalyst.

H)The dust content of exhaust gas should not be exceed 10mg/m3, otherwise it is easy to cause the blockage of catalyst channel. If it is difficult to reduce the dust to the ideal state before treatment, it is recommended to regularly remove the catalyst and blow it with an air gun before use, without washing it with water or any liquid.

I)When the catalyst is used for a long time, there is a certain decrease in activity, the catalytic bed can be switched before and after or up and down, or the operating temperature of the catalytic chamber can be appropriately increased.

J)When the temperature of the catalytic furnace is higher than 450℃, it is recommended to start the supplementary cooling fan and fill cold air to cool the catalytic furnace to protect the catalyst.

6)Technical support

Based on working temperature, gas composition, concentration, air volume, purification rate, etc. Xintan team can offer advice on composition and dosage of precious metals needed for your device.

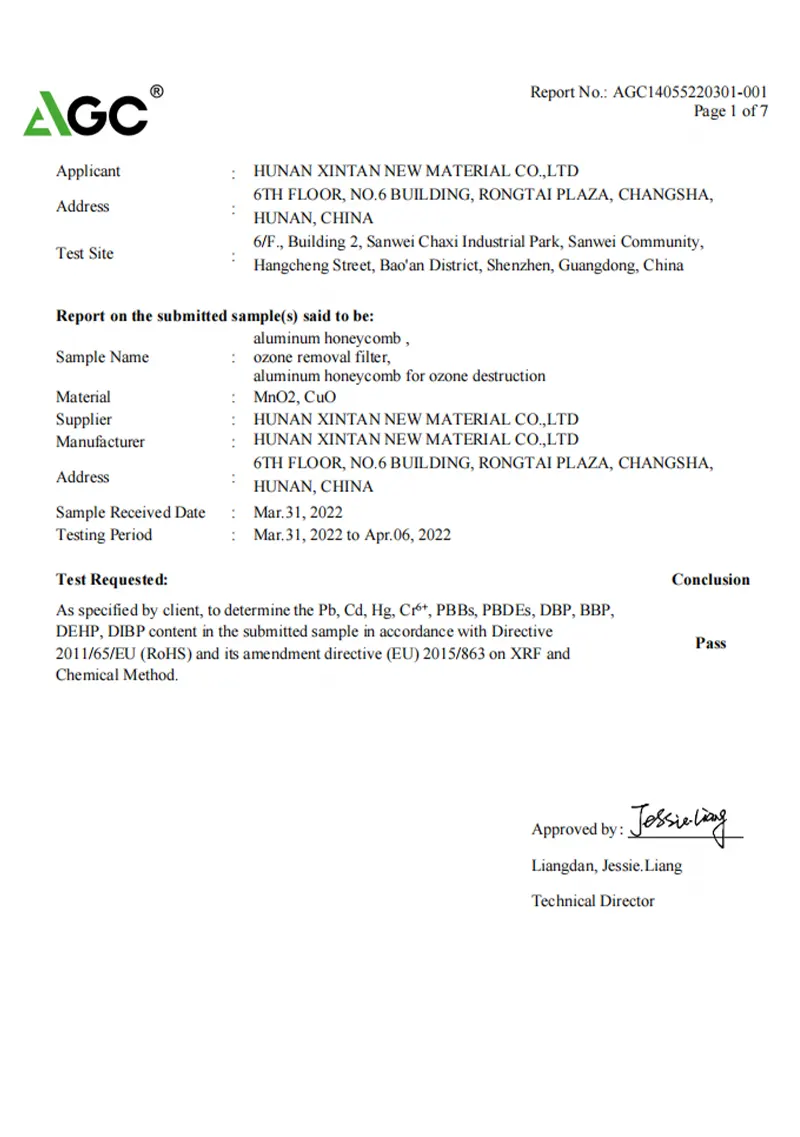

Qualification Certificate

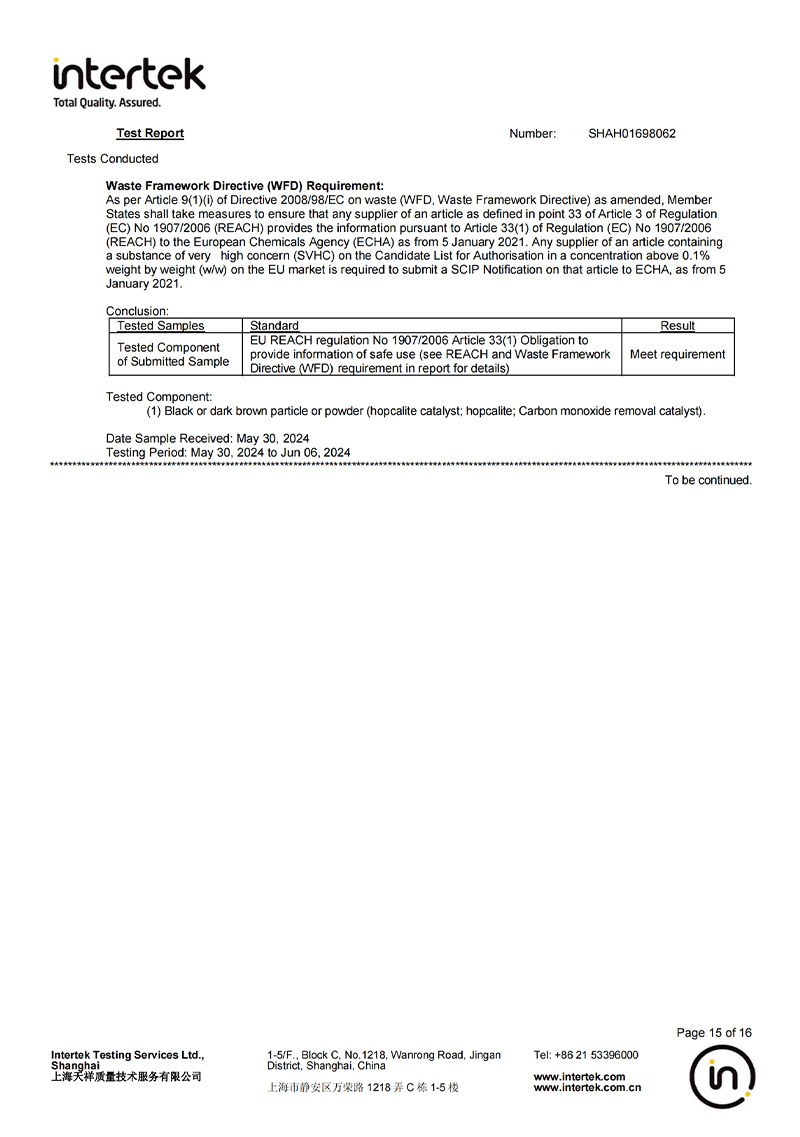

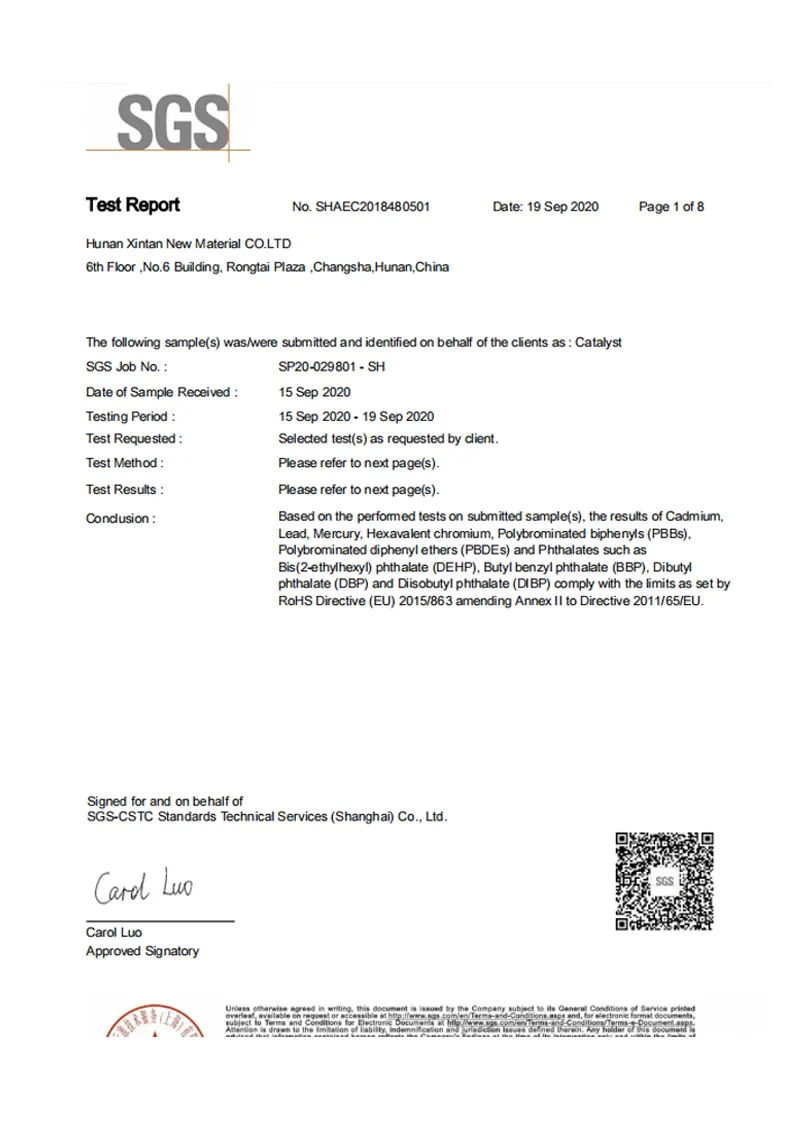

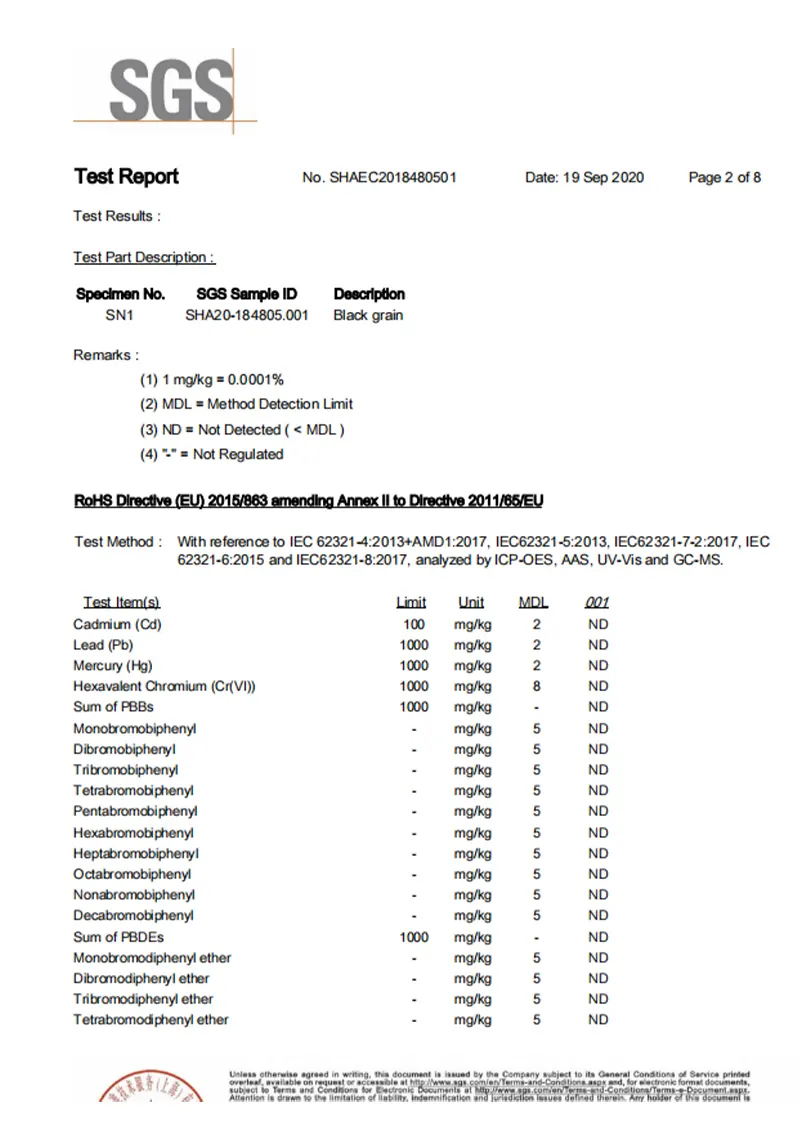

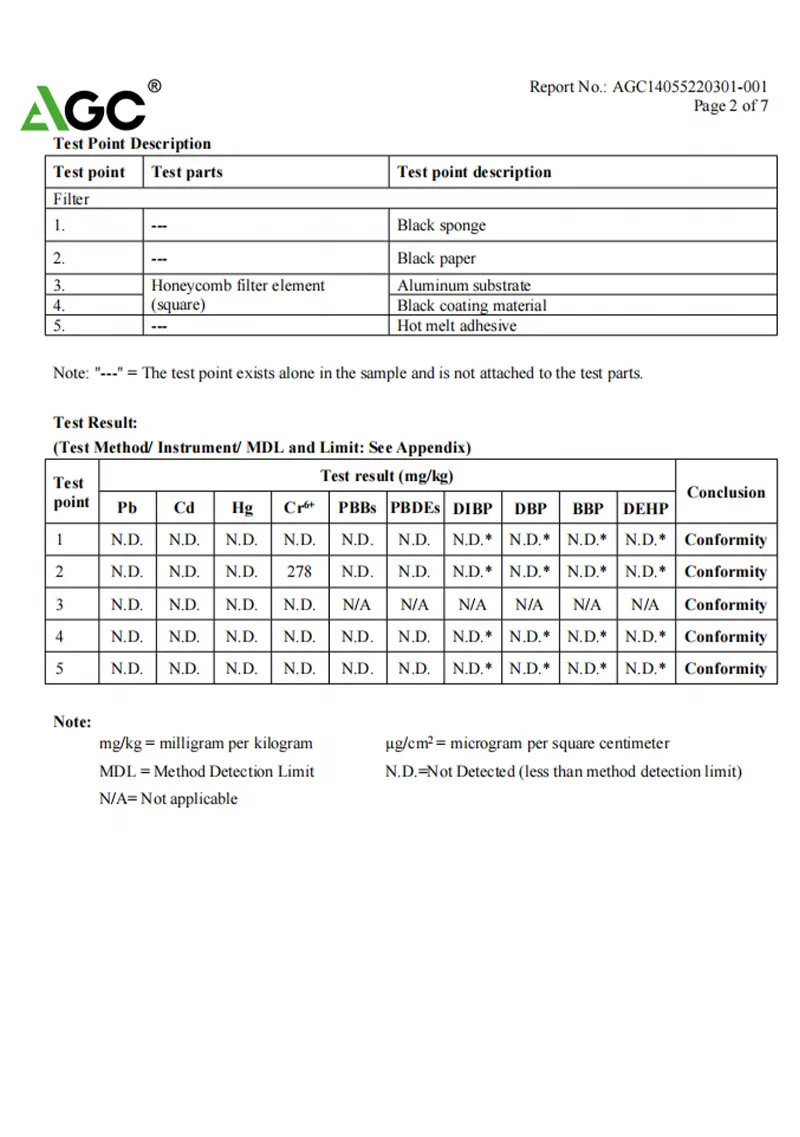

Test Report

Quality Management System Certificate

SGS

SGS

AGC

AGC

Related Products

Carbon molecular sieve, which are composed of elemental carbon, are a new type of adsorbent and an excellent non-polar carbon material. Hunan Xintan carbon molecular sieve is black columnar particles with a diameter of 1.0-1.3mm or customized. The product has the characteristics of strong nitrogen production capacity, high nitrogen recovery rate, long service life and low production cost. Carbon molecular sieve contain a large number of micropores, which have a strong instantaneous affinity for oxygen molecules and can be used to separate O2 and N2 in the air. In industry, carbon molecular sieves are often used in pressure swing adsorption (PSA) nitrogen production, which is suitable for various types of pressure swing adsorption nitrogen generators.

CO removal catalyst (Ceramic honeycomb)

CO removal catalyst (Honeycomb) uses cordierite honeycomb ceramic as a carrier and is a highly active catalyst prepared from a variety of rare earth metals. The CO removal catalyst (Honeycomb) produced by Hunan Xintan has the characteristics of high structural strength, strong surface coating adhesion, and is not easy to fall off. This catalyst can not only be used to treat carbon monoxide in flue gas, but also has high catalytic performance in chlorine-containing working conditions, and can be used for the treatment of chlorine-containing organic waste gas, and is widely used in the treatment ofsteel flue gas, lime kiln flue gas, waste incineration smoke and other smoke.

CO removal catalyst (Pt and Pd)

CO removal catalyst (pellet with Pt and Pd) is a precious metal palladium catalyst with alumina as a carrier. The carbon monoxide precious metal catalyst produced by Hunan Xintan is dark brown spherical particles with a diameter of 3-5mm, which is mainly used to remove H2 and CO at 20℃~300℃. The catalyst can convert CO to CO2 and H2 to H2O. It does not contain MnO2, CuO or S, so it can be safely used for CO purification in CO2. CO removal catalyst (pellet with Pt and Pd) have the characteristics of high catalytic efficiency, stable performance, safety, no energy consumption and long service life, and are widely used in the food industry.

CuO catalyst (for removing oxygen from Nitrogen or Methanol Synthesis)

CuO catalyst (for removing oxygen from Nitrogen or Methanol Synthesis) developed by Hunan Xintan is made of a high proportion of copper oxide (CuO) and inert metal oxides. It is a black cylindrical particle with a diameter of 5mm and a length of 5mm. The catalyst has the characteristics of high active component content, high packing density, low cost and long service life. It is a catalyst used to remove oxygen from nitrogen or inert gases such as helium and argon, which can efficiently convert oxygen to CuO without the need for additional energy. It does not contain any dangerous substances. The catalyst is widely used in gas treatment because of its high efficiency. The catalytic deoxidation reaction equation is as follows: CuO+H2=Cu+H2O 2Cu+O2=2CuO