CuO catalyst (for removing oxygen from Nitrogen or Methanol Synthesis)

Model: XT-CAT-03

Uses: removing O2 or H2

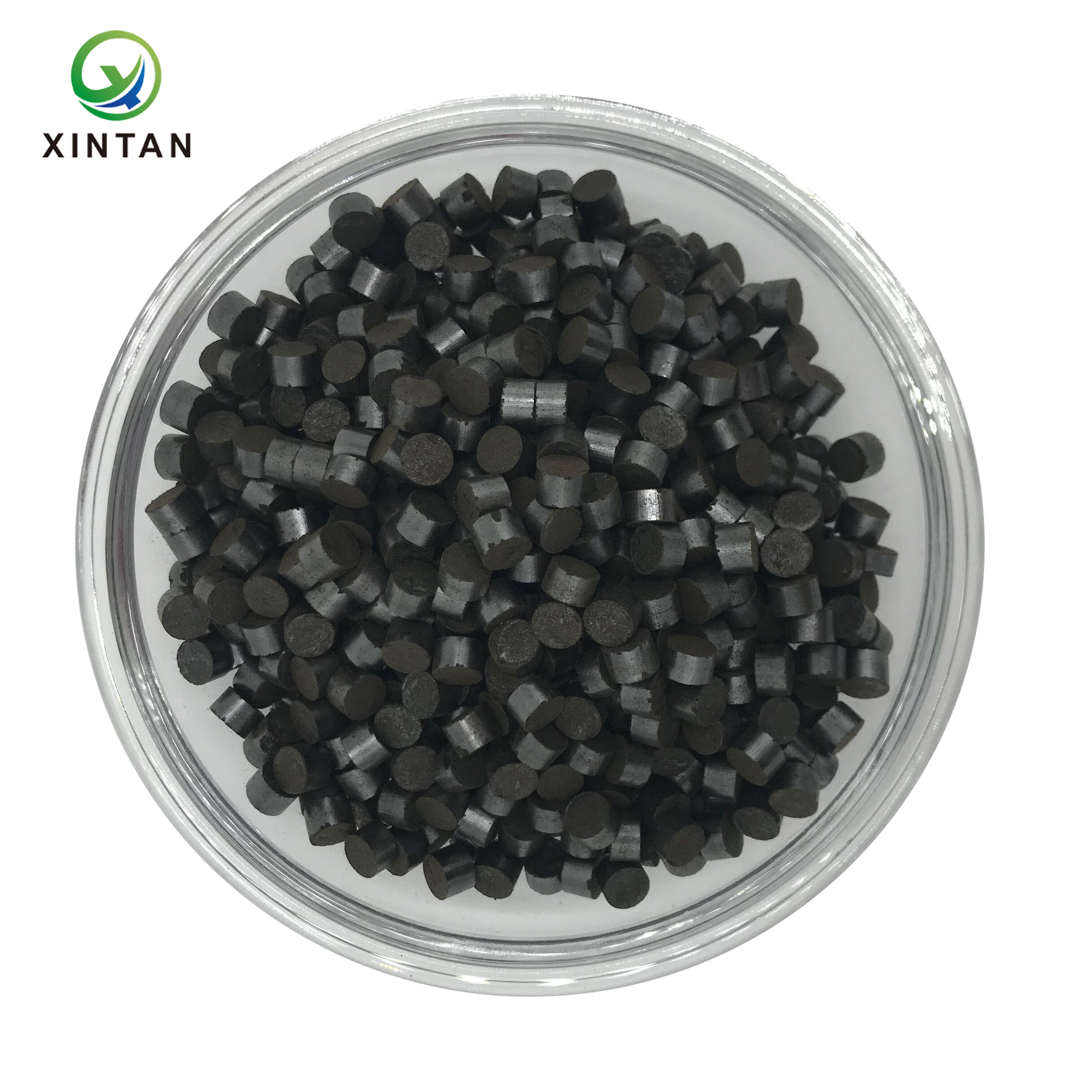

Shape: black cylindrical. Ф 5mm

Composition: CuO

Characteristic: high CuO content and packing density; Long service life

Index: See product details for specific parameters

Package: 35kg or 40kg iron drum or plastic drum, under 20kg, packed in cartons

Application area: used to remove oxygen from inert gases such as nitrogen, helium and argon, and is widely used in gas treatment.

Product Details

1)Product introduction

CuO catalyst (for removing oxygen from Nitrogen or Methanol Synthesis) developed by Hunan Xintan is made of a high proportion of copper oxide (CuO) and inert metal oxides. It is a black cylindrical particle with a diameter of 5mm and a length of 5mm. The catalyst has the characteristics of high active component content, high packing density, low cost and long service life. It is a catalyst used to remove oxygen from nitrogen or inert gases such as helium and argon, which can efficiently convert oxygen to CuO without the need for additional energy. It does not contain any dangerous substances. The catalyst is widely used in gas treatment because of its high efficiency. The catalytic deoxidation reaction equation is as follows:

CuO+H2=Cu+H2O

2Cu+O2=2CuO

2)Parameters

|

Ingredients |

CuO and mixture of inert metal oxides |

|

Shape |

Columnar |

|

Size |

Diameter:5mm Length: 5mm |

|

Bulk density |

1300kg/m3 |

|

Surface area |

>200 m2/g |

|

Working Temperature and Humidity |

0~250℃ |

|

Working life |

5 years |

3)Product advantages

A)High CuO content. The content of CuO is more than 65%;

B)High packing density. The bulk density of this catalyst can reach 1300kg/m3, which make its working life longer than same types of products.;

C)Long service life. The service life of Xintan CuO catalyst (for removing oxygen from Nitrogen) can reach 5 years.

D)Low cost. Compared with other method of deoxygenation, catalytic deoxygenation is safe and cost-effective

4)Applications

Industrial nitrogen production: As a new type of industrial raw materials, industrial gas has been more and more widely used in various fields of the national economy. High purity nitrogen has important applications in metallurgy, electronics and food industries as a dry gas source. Nitrogen is usually mixed with oxygen before filtration, and the oxygen can be oxidized by a catalyst to reduce the purity of the nitrogen. So it's necessary to remove the oxygen from the nitrogen.

5) Remark:

A)Keep dry and sealed when storing.

B)Keep away from sulfide, chlorine and mercury.

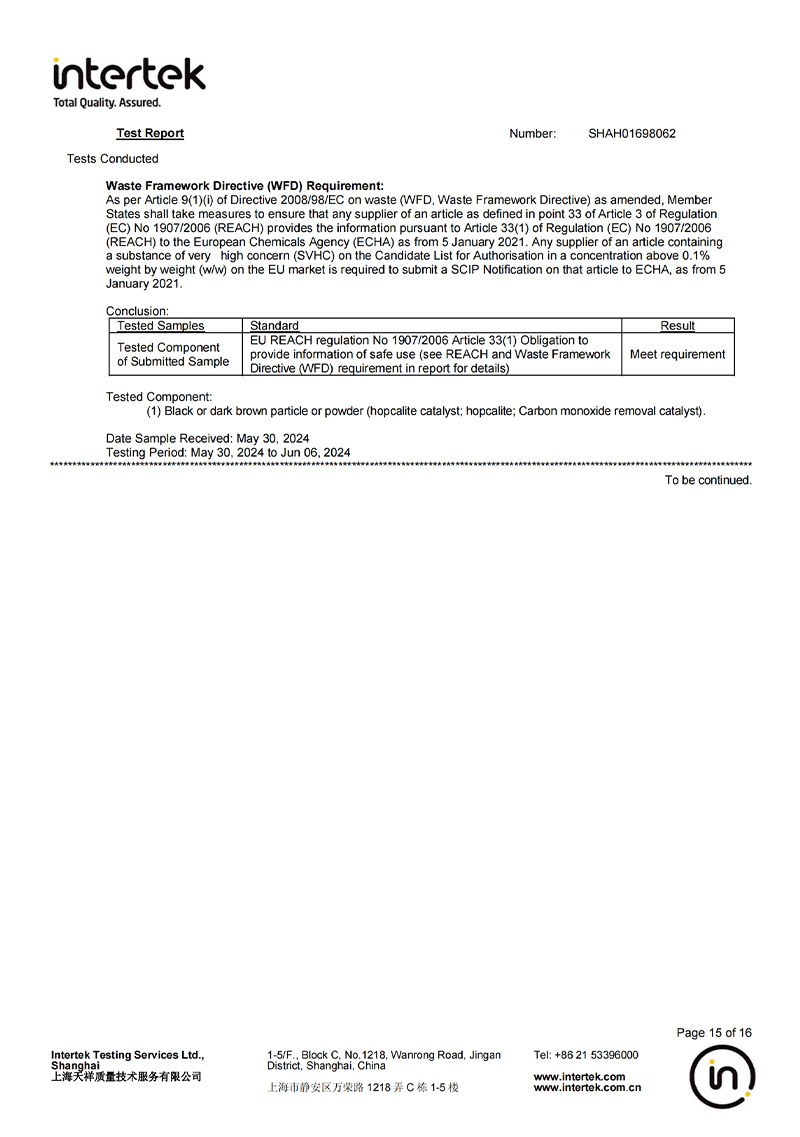

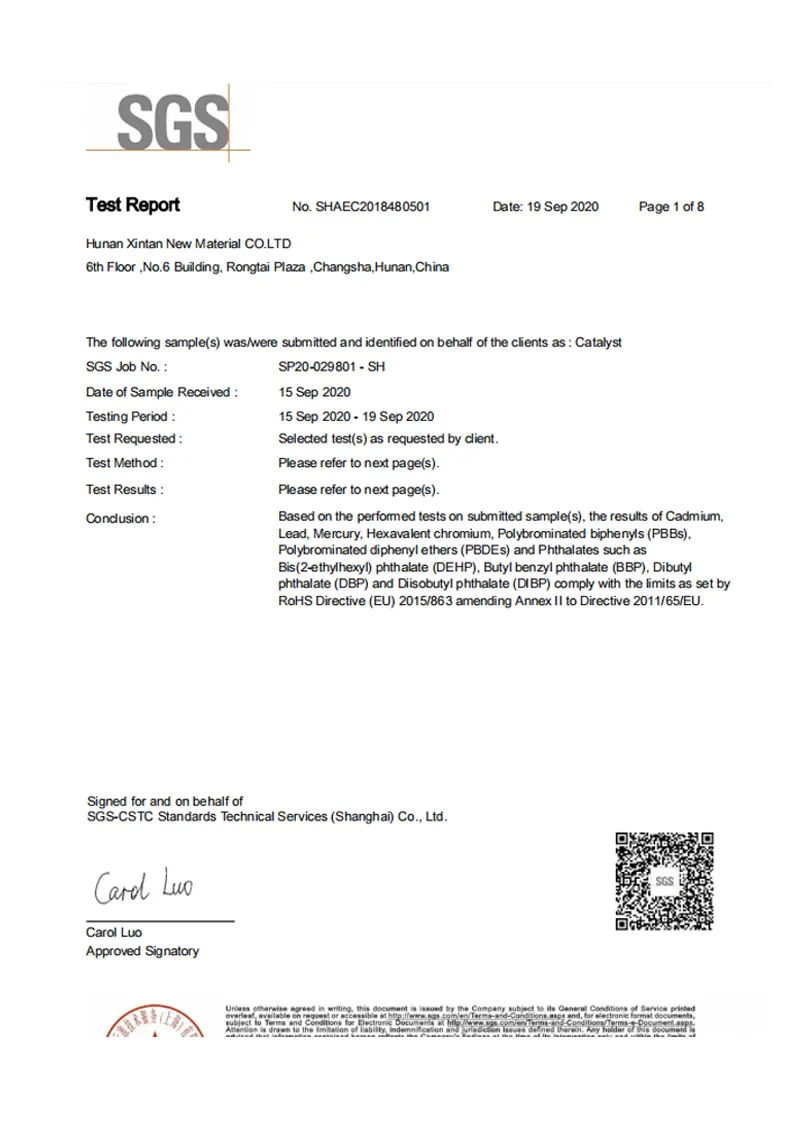

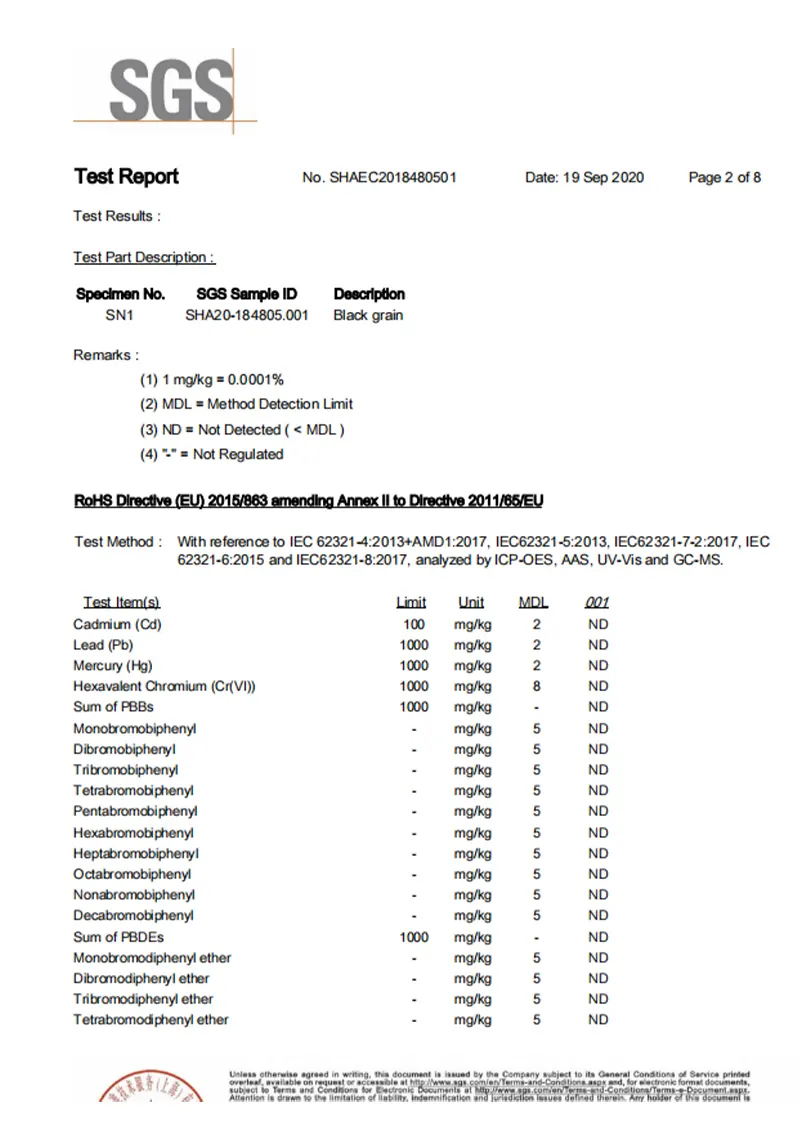

Qualification Certificate

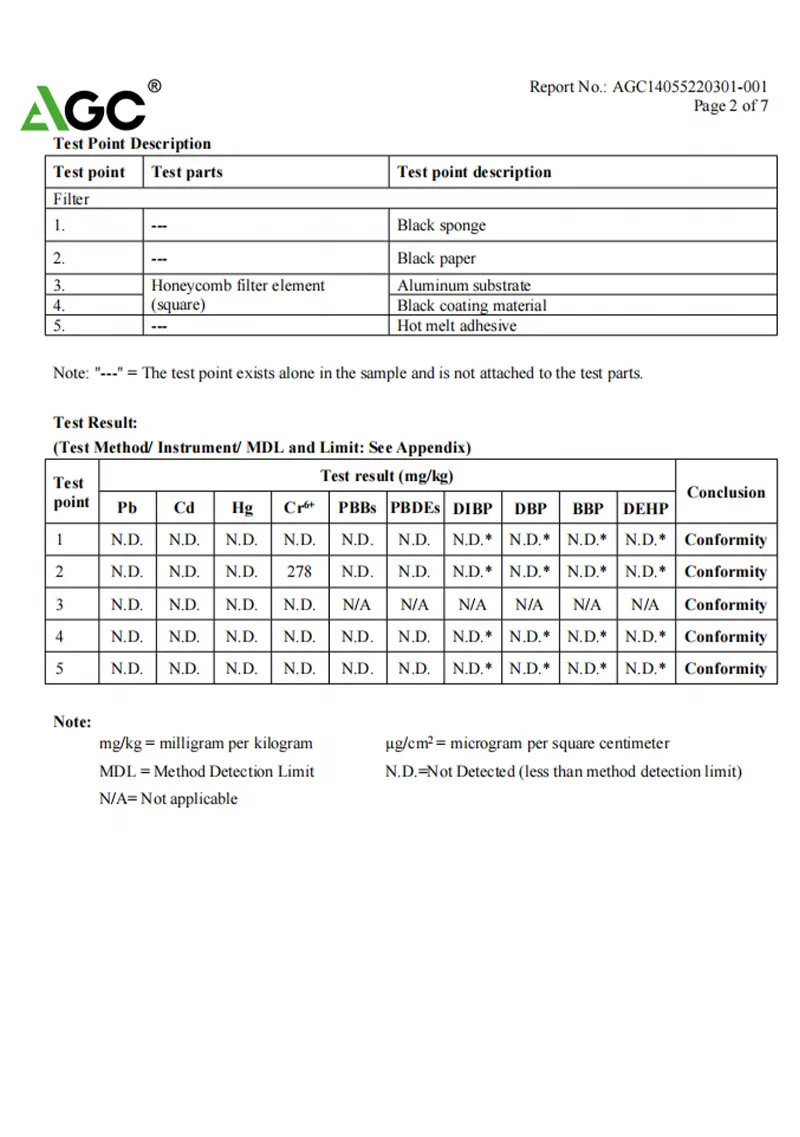

Test Report

Quality Management System Certificate

SGS

SGS

AGC

AGC

Related Products

Carbon molecular sieve, which are composed of elemental carbon, are a new type of adsorbent and an excellent non-polar carbon material. Hunan Xintan carbon molecular sieve is black columnar particles with a diameter of 1.0-1.3mm or customized. The product has the characteristics of strong nitrogen production capacity, high nitrogen recovery rate, long service life and low production cost. Carbon molecular sieve contain a large number of micropores, which have a strong instantaneous affinity for oxygen molecules and can be used to separate O2 and N2 in the air. In industry, carbon molecular sieves are often used in pressure swing adsorption (PSA) nitrogen production, which is suitable for various types of pressure swing adsorption nitrogen generators.

CO removal catalyst (Ceramic honeycomb)

CO removal catalyst (Honeycomb) uses cordierite honeycomb ceramic as a carrier and is a highly active catalyst prepared from a variety of rare earth metals. The CO removal catalyst (Honeycomb) produced by Hunan Xintan has the characteristics of high structural strength, strong surface coating adhesion, and is not easy to fall off. This catalyst can not only be used to treat carbon monoxide in flue gas, but also has high catalytic performance in chlorine-containing working conditions, and can be used for the treatment of chlorine-containing organic waste gas, and is widely used in the treatment ofsteel flue gas, lime kiln flue gas, waste incineration smoke and other smoke.

CO removal catalyst (Pt and Pd)

CO removal catalyst (pellet with Pt and Pd) is a precious metal palladium catalyst with alumina as a carrier. The carbon monoxide precious metal catalyst produced by Hunan Xintan is dark brown spherical particles with a diameter of 3-5mm, which is mainly used to remove H2 and CO at 20℃~300℃. The catalyst can convert CO to CO2 and H2 to H2O. It does not contain MnO2, CuO or S, so it can be safely used for CO purification in CO2. CO removal catalyst (pellet with Pt and Pd) have the characteristics of high catalytic efficiency, stable performance, safety, no energy consumption and long service life, and are widely used in the food industry.

Hopcalite catalyst, also known as carbon monoxide (CO) removal catalyst, is made of a certain proportion of MnO2 and CuO through bonding mixing and mechanical processing. The catalyst is black or dark brown columnar particles with a diameter of 1.1mm or 3mm. It is a catalyst that removes CO by oxidizing CO to CO2. The hopcalite catalyst produced by Hunan Xintan can catalyze the reaction of CO and O2 quickly and efficiently under the condition of 20~200℃, converting CO into CO2, which has the characteristics of high efficiency, high catalytic activity, energy saving, long service life and low maintenance cost. Xintan hopcalite catalyst is widely used in nitrogen (N2), gas masks, refuge chambers, compressed air breathing equipment and other industrial gas treatment.