Calcined Petroleum Coke (CPC)

Model: XT-C01/XT-C02/XT-C03/XT-C04

Uses: Raw material of GPC, increase carbon for low-end foundry parts

Shape: 1-5mm/0.5-5mm/0.2-1mm/40-100 mesh, etc

Composition: 98.5% min C, 0.5-1.5%max S

Characteristic: high temperature calcination; high carbon content,low-cost

Index: See product details for specific parameters

Package: (20KG/25KG) small bags into Ton bag

Application area: in the casting industry for the carburization of gray iron castings; used as filler in the graphitization of negative electrode materials; automotive brake pads industry to enhance product friction coefficient.

Product Details

1)Product introduction

Calcined petroleum coke is also known as recarburizer, calcined coke, petroleum coke, calcined petroleum coke recarburizer produced by Xintan is calcined by calcination furnace at 1250℃ temperature, effectively remove harmful substances of products, reduce volatiles and ash, and then through crushing, screening, packaging and other processes. The appearance is gray-black granular, porous. It can be processed into 0-50mm different specs. according to customer requirements, such as 1-5mm, 0.2-1mm, 0-1mm and so on. Calcined petroleum coke is raw coke by calcination and purification processing, appearance into a round grain or prismatic, has the characteristics of high carbon, low sulfur and low ash. Calcined petroleum coke is mainly used for pre-baked anode and anode paste for electrolytic aluminum, carbon industry production of carbonizing agent, graphite electrode, smelting industrial silicon and fuel.

2)Parameters

|

Model No |

C(≥%) |

S(≤%) |

Moisture(≤%) |

Ash(≤%) |

Volatiles(≤%) |

|

XT-C01 |

98.5 |

0.5 |

0.5 |

0.8 |

0.7 |

|

XT-C02 |

98.5 |

0.7 |

0.5 |

0.8 |

0.7 |

|

XT-C03 |

98.5 |

0.8 |

0.5 |

0.8 |

0.7 |

|

XT-C04 |

98.5 |

1.5 |

0.5 |

0.8 |

0.7 |

3)Product advantages

A)High carbon content. High degree of graphitization, excellent purity, carbon content of graphitized petroleum coke is more than 98.5%, used in iron and steel smelting, casting and forging processes, can improve the carbon content of castings, improve the mechanical properties of castings, improve hardness and wear resistance.

B)High hardness. In the field of iron and steel smelting and non-ferrous metal smelting, calcined petroleum coke can be used as refractory and supporting material to withstand high temperature and mechanical pressure.

C)Wide range of applications. Calcined petroleum coke can be processed into graphitized petroleum coke, and can also be used for graphite electrode, carbon paste, fuel and many other purposes.

4)Applications

According to the different sulfur content, the calcined petroleum coke can be divided into low sulfur coke, medium sulfur coke and high sulfur coke:

Applications of low-sulfur coke:

a) Used as an insulator and filler in the manufacture of graphite electrodes and special carbon products.

b) Metallurgical casting: as a carburizer or reducing agent.

c) Negative battery: low sulfur coke ground into fine powder, can be used for the negative battery.

d) Steel and casting: low sulfur coke has the characteristics of high carbon content and low sulfur content, and can also be used as a recarburizer.

e) Oil drilling platform.

Applications of high sulfur coke:

a) Anode and cathode of pre-baked electrolytic aluminum.

b) Carbon paste products.

c) Used as fuel:as chemical production, silicon carbide or a fuel for metal manufacturing, glass plants, etc.

5)Remark:

Keep dry when storing to avoid moisture.

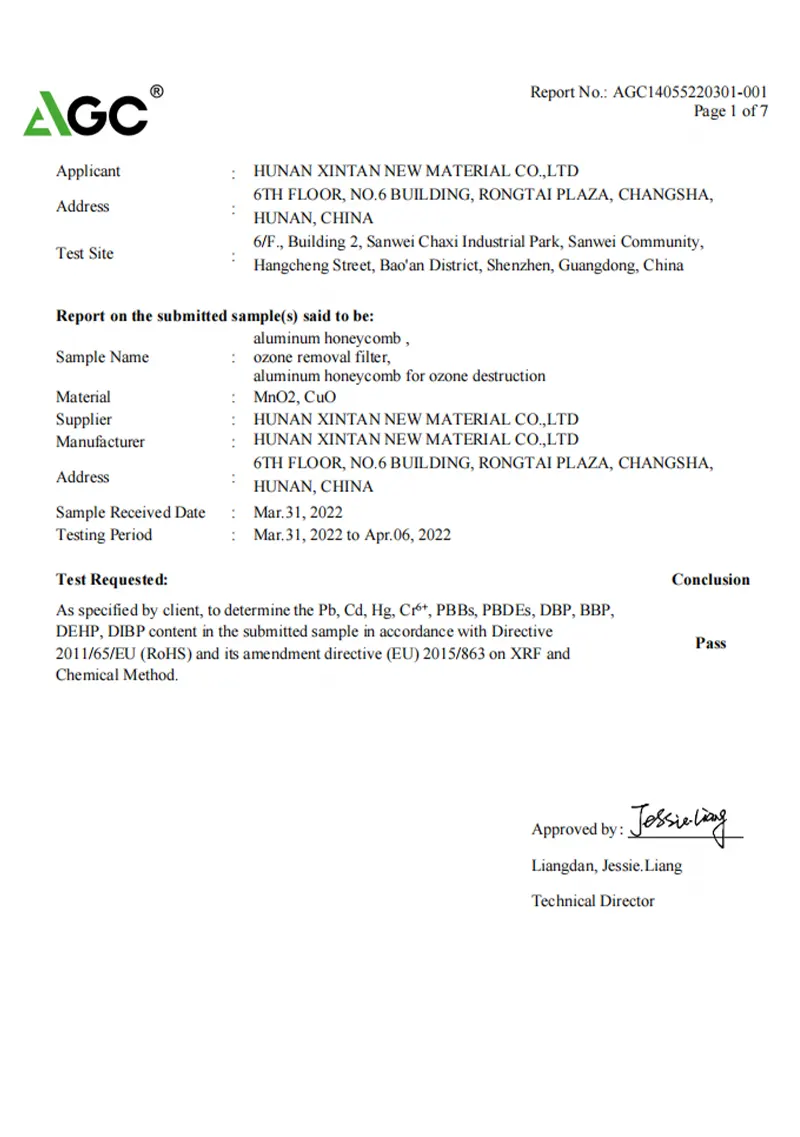

Qualification Certificate

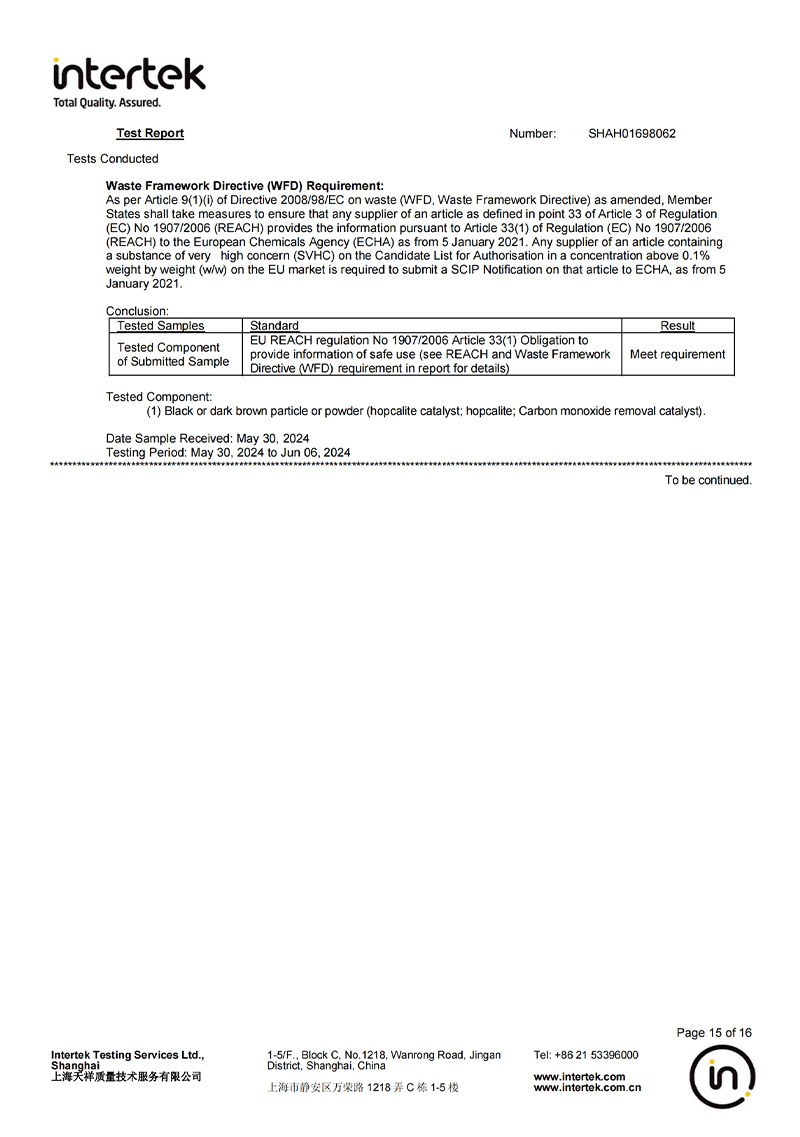

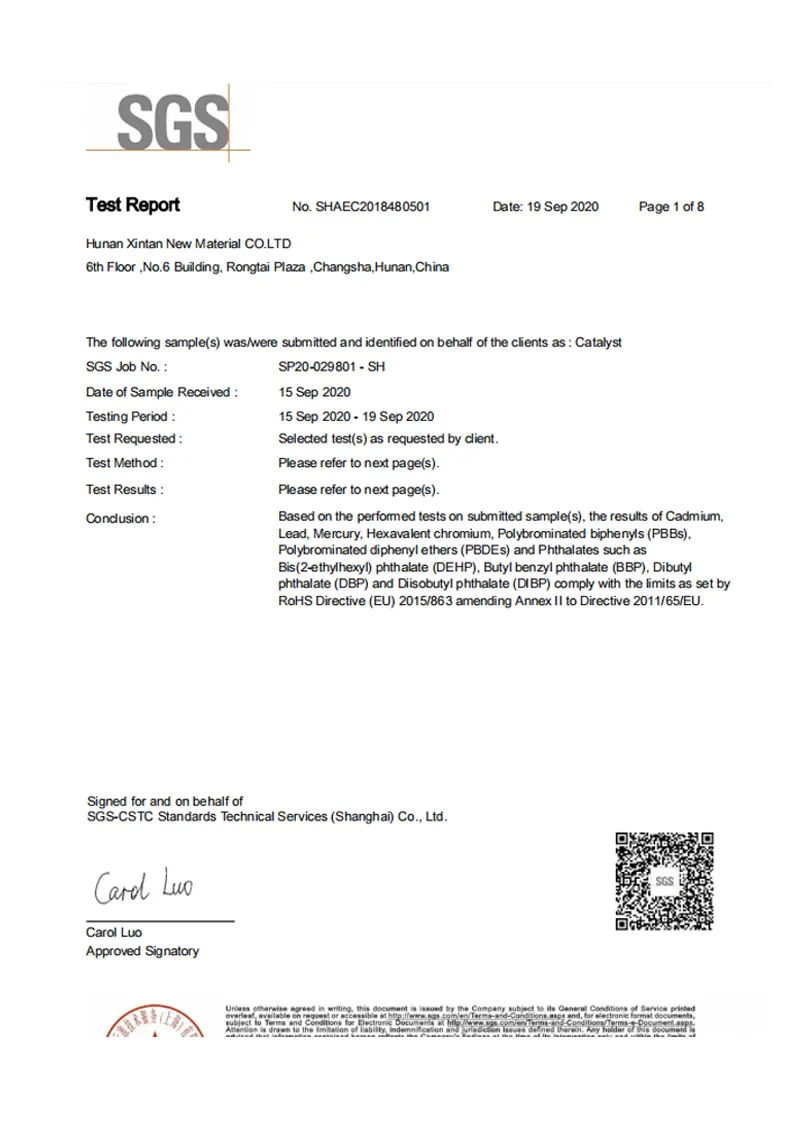

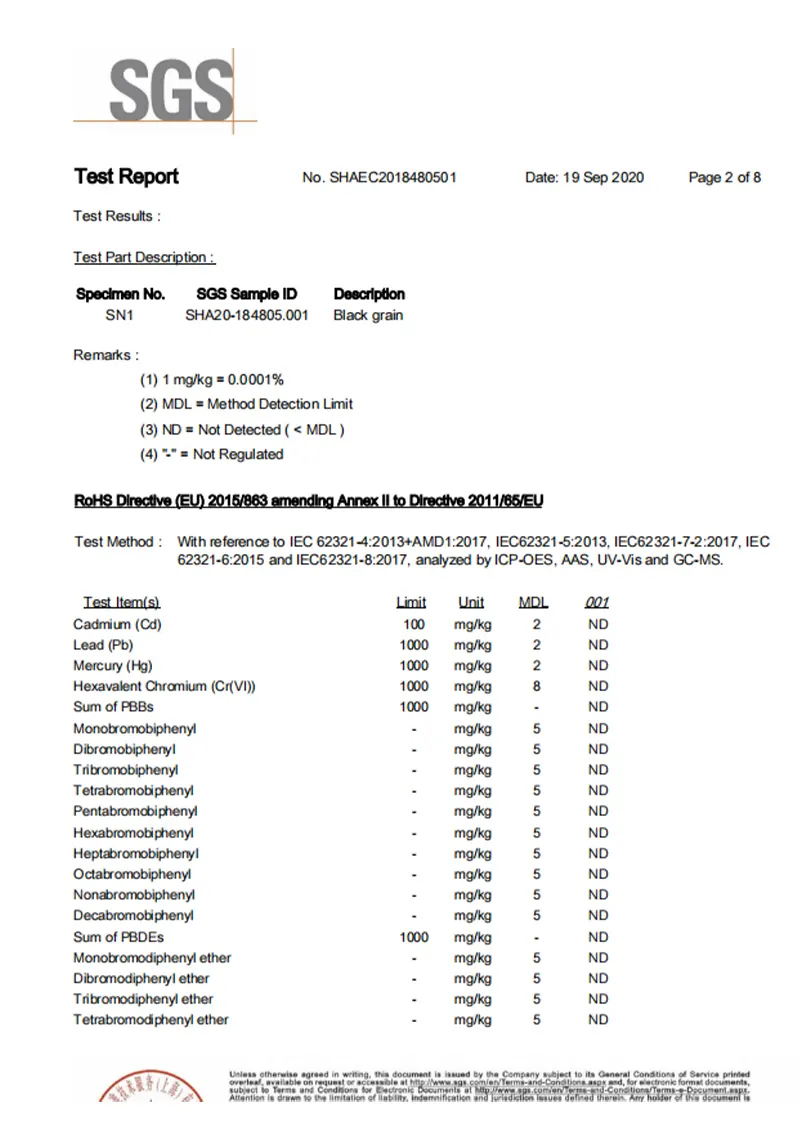

Test Report

Quality Management System Certificate

SGS

SGS

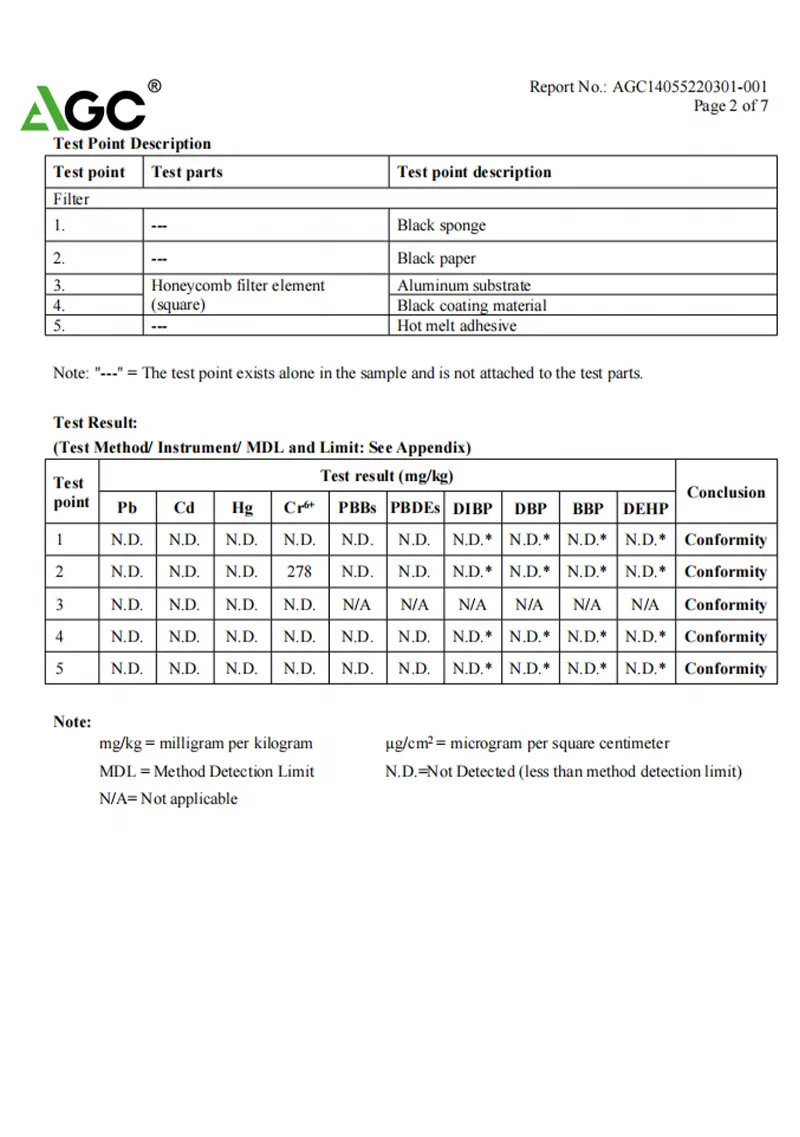

AGC

AGC

Related Products

Carbon molecular sieve, which are composed of elemental carbon, are a new type of adsorbent and an excellent non-polar carbon material. Hunan Xintan carbon molecular sieve is black columnar particles with a diameter of 1.0-1.3mm or customized. The product has the characteristics of strong nitrogen production capacity, high nitrogen recovery rate, long service life and low production cost. Carbon molecular sieve contain a large number of micropores, which have a strong instantaneous affinity for oxygen molecules and can be used to separate O2 and N2 in the air. In industry, carbon molecular sieves are often used in pressure swing adsorption (PSA) nitrogen production, which is suitable for various types of pressure swing adsorption nitrogen generators.

CO removal catalyst (Ceramic honeycomb)

CO removal catalyst (Honeycomb) uses cordierite honeycomb ceramic as a carrier and is a highly active catalyst prepared from a variety of rare earth metals. The CO removal catalyst (Honeycomb) produced by Hunan Xintan has the characteristics of high structural strength, strong surface coating adhesion, and is not easy to fall off. This catalyst can not only be used to treat carbon monoxide in flue gas, but also has high catalytic performance in chlorine-containing working conditions, and can be used for the treatment of chlorine-containing organic waste gas, and is widely used in the treatment ofsteel flue gas, lime kiln flue gas, waste incineration smoke and other smoke.

CO removal catalyst (Pt and Pd)

CO removal catalyst (pellet with Pt and Pd) is a precious metal palladium catalyst with alumina as a carrier. The carbon monoxide precious metal catalyst produced by Hunan Xintan is dark brown spherical particles with a diameter of 3-5mm, which is mainly used to remove H2 and CO at 20℃~300℃. The catalyst can convert CO to CO2 and H2 to H2O. It does not contain MnO2, CuO or S, so it can be safely used for CO purification in CO2. CO removal catalyst (pellet with Pt and Pd) have the characteristics of high catalytic efficiency, stable performance, safety, no energy consumption and long service life, and are widely used in the food industry.

CuO catalyst (for removing oxygen from Nitrogen or Methanol Synthesis)

CuO catalyst (for removing oxygen from Nitrogen or Methanol Synthesis) developed by Hunan Xintan is made of a high proportion of copper oxide (CuO) and inert metal oxides. It is a black cylindrical particle with a diameter of 5mm and a length of 5mm. The catalyst has the characteristics of high active component content, high packing density, low cost and long service life. It is a catalyst used to remove oxygen from nitrogen or inert gases such as helium and argon, which can efficiently convert oxygen to CuO without the need for additional energy. It does not contain any dangerous substances. The catalyst is widely used in gas treatment because of its high efficiency. The catalytic deoxidation reaction equation is as follows: CuO+H2=Cu+H2O 2Cu+O2=2CuO