Application of Palladium Catalysts in Industrial Gas Purification

Removal and Purification of Oxygen and Hydrogen in Industrial Gases

1. Hydrogenation Deoxygenation Purification

Application Scenario: Suitable for removing trace amounts of oxygen in inert gases such as hydrogen, nitrogen, and carbon dioxide. It achieves deep deoxygenation through catalytic hydrogenation reaction (O₂ + 2H₂ → 2H₂O).

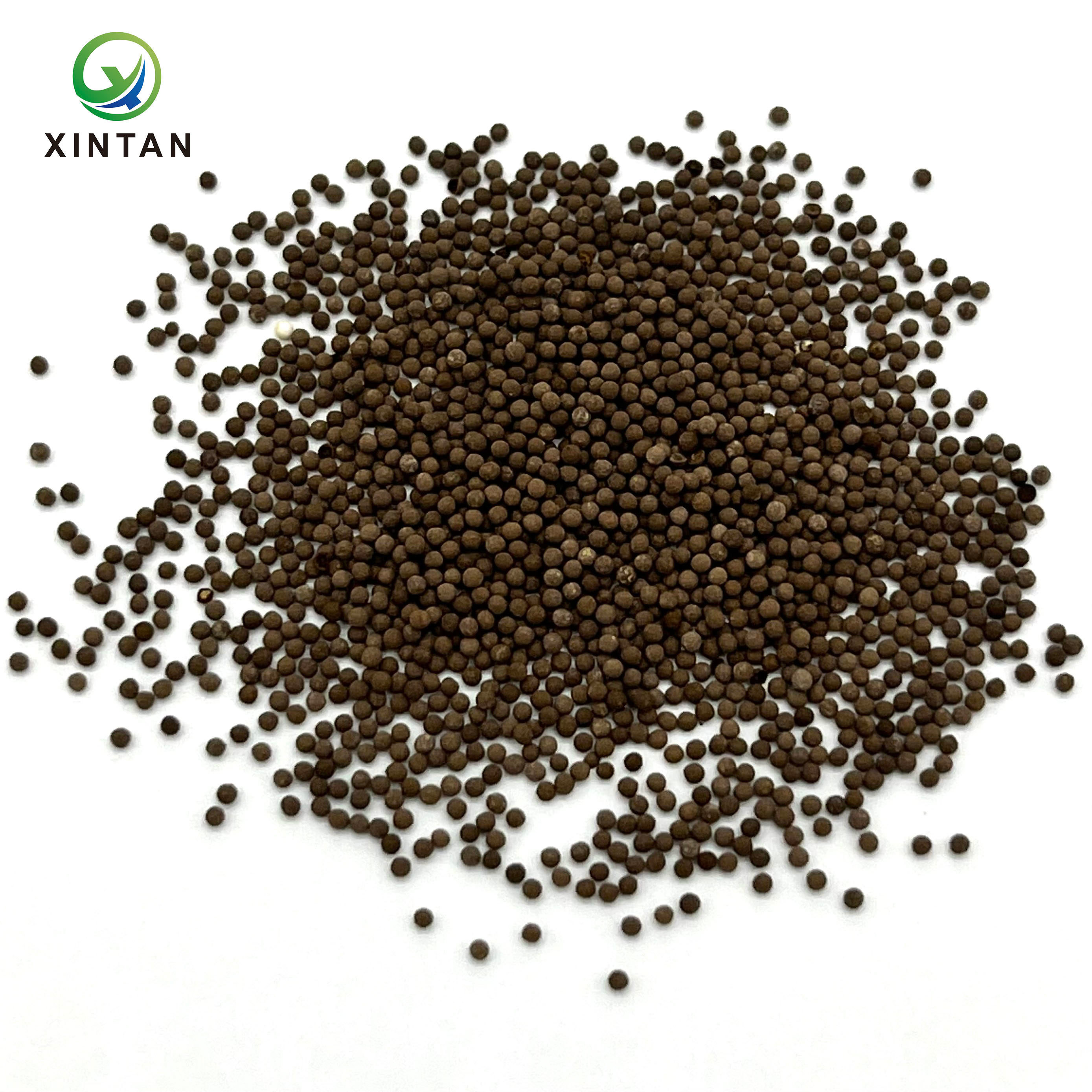

Technical Advantages: The catalyst has a large pore volume, high specific surface area (about 250 m²/g) and high compressive strength (≥ 50 N/particle), and has a wide speed range adaptation (5000 - 15000 h⁻¹), with purification efficiency reaching over 98%.

2. Dehydrogenation Purification

Application Object: For inert gases such as nitrogen and argon, as well as excess hydrogen in CO and CO₂, a palladium-based dehydrogenation catalyst (such as SODH type) is used. At normal temperature to 160°C, hydrogen reacts with the "solid oxygen" on the catalyst surface to form water, and the residual hydrogen content can be reduced to ≤ 1 ppm.

Related News