Product Details

Qualification Certificate

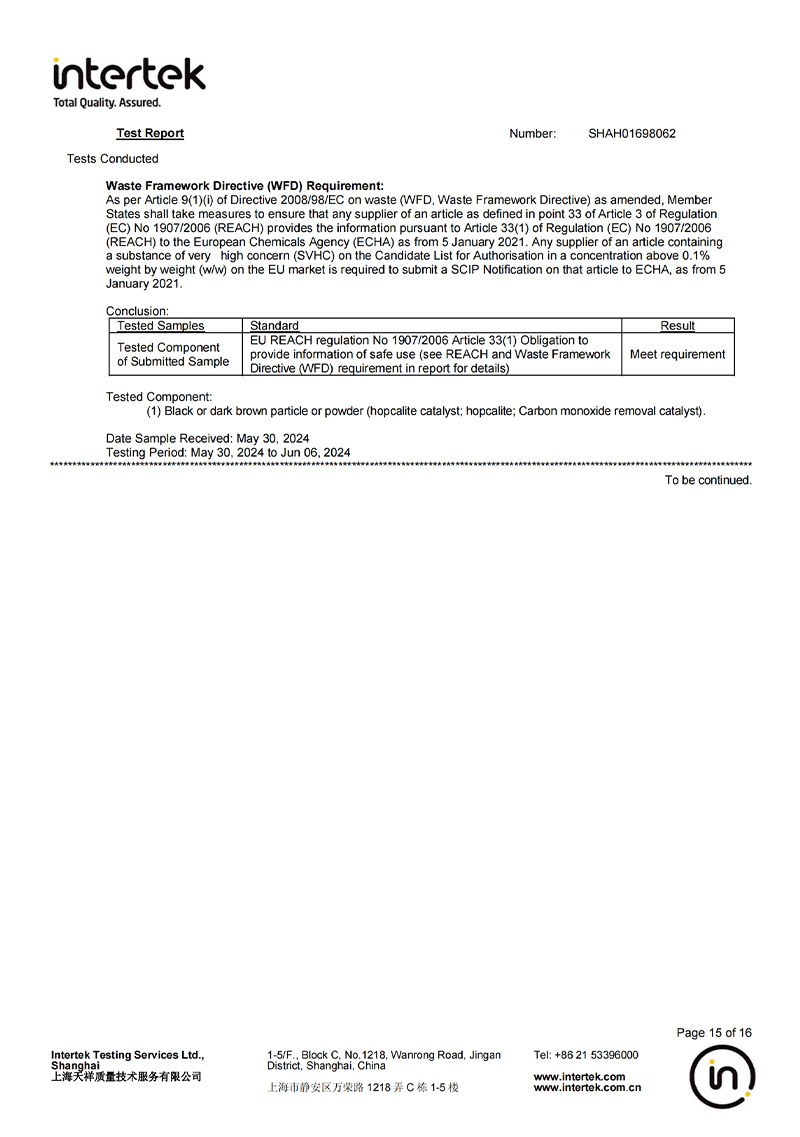

Test Report

Quality Management System Certificate

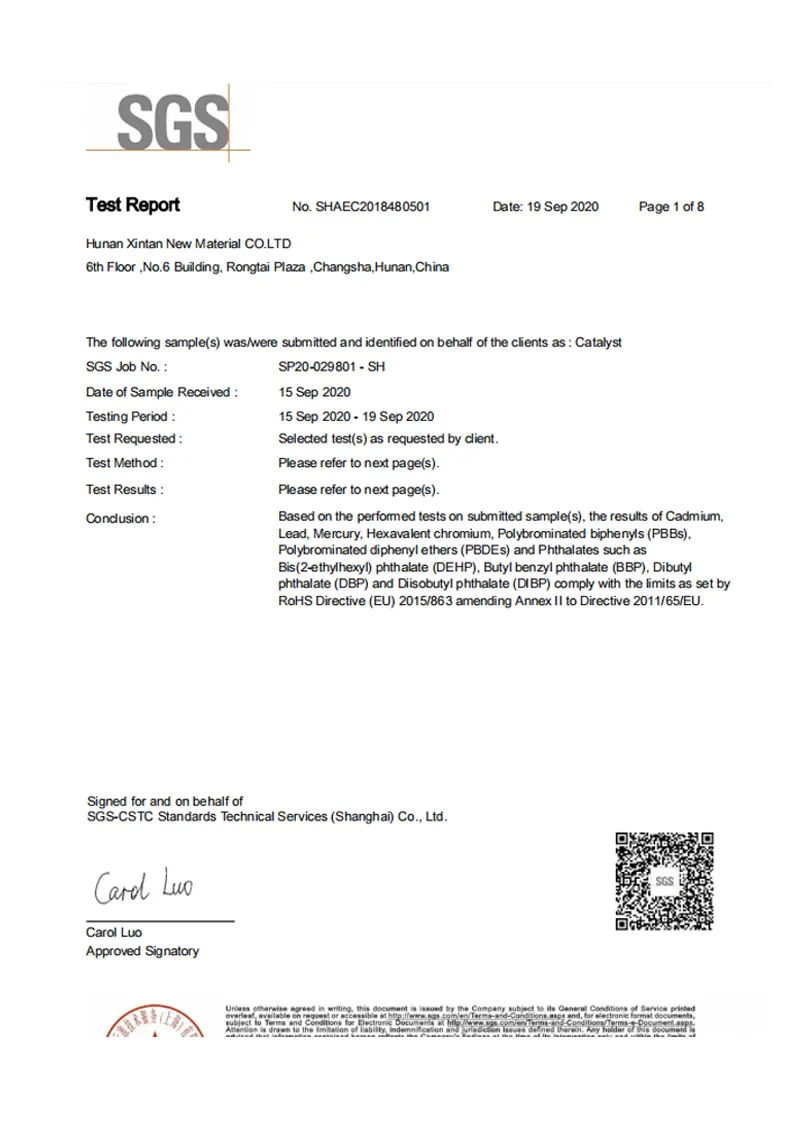

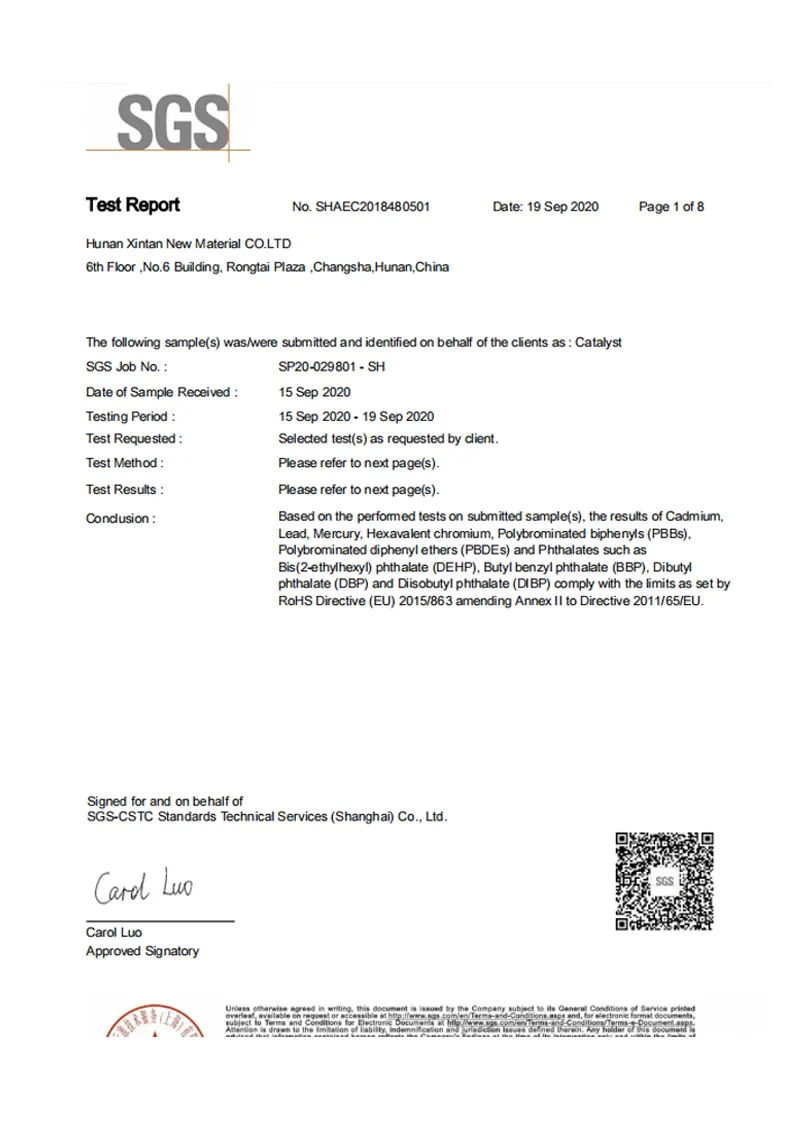

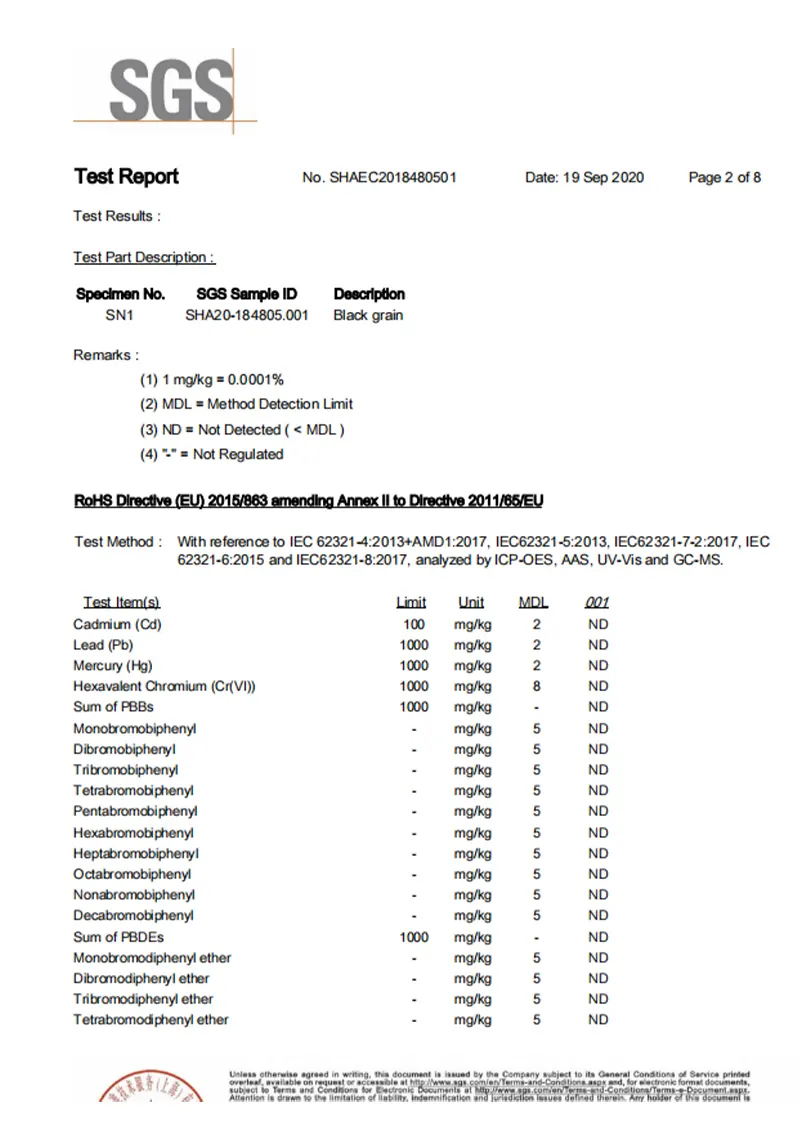

SGS

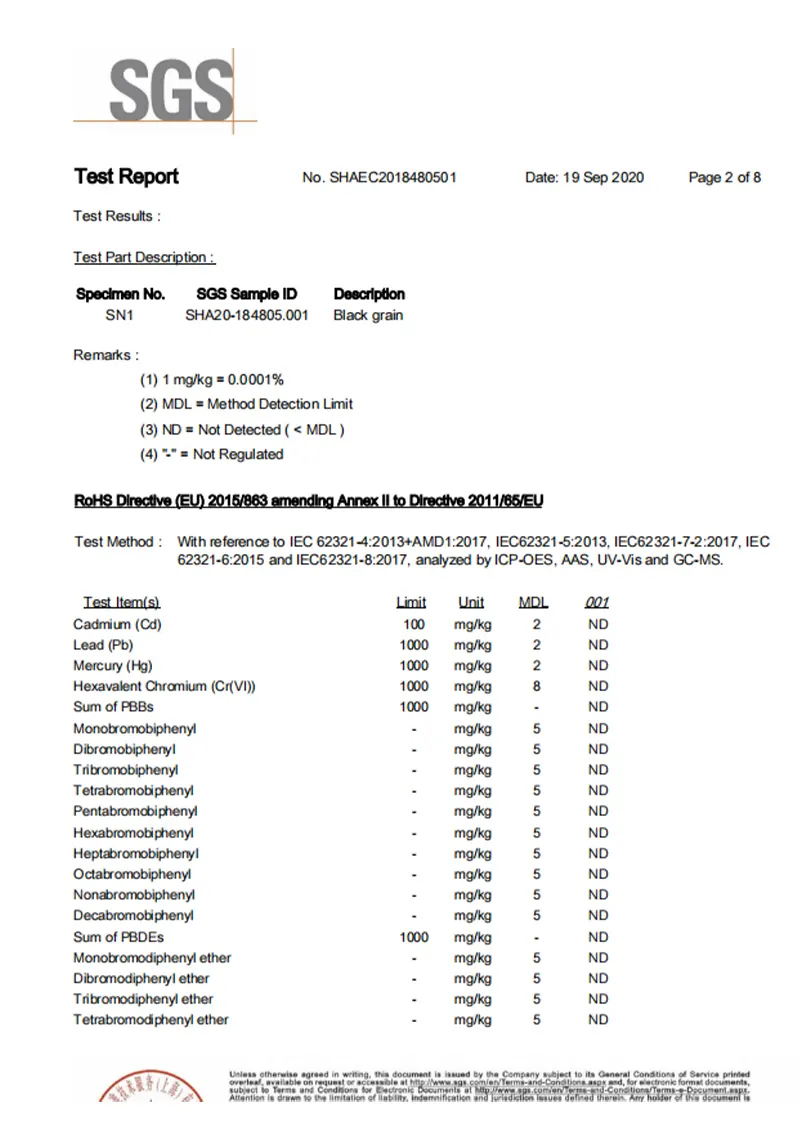

SGS

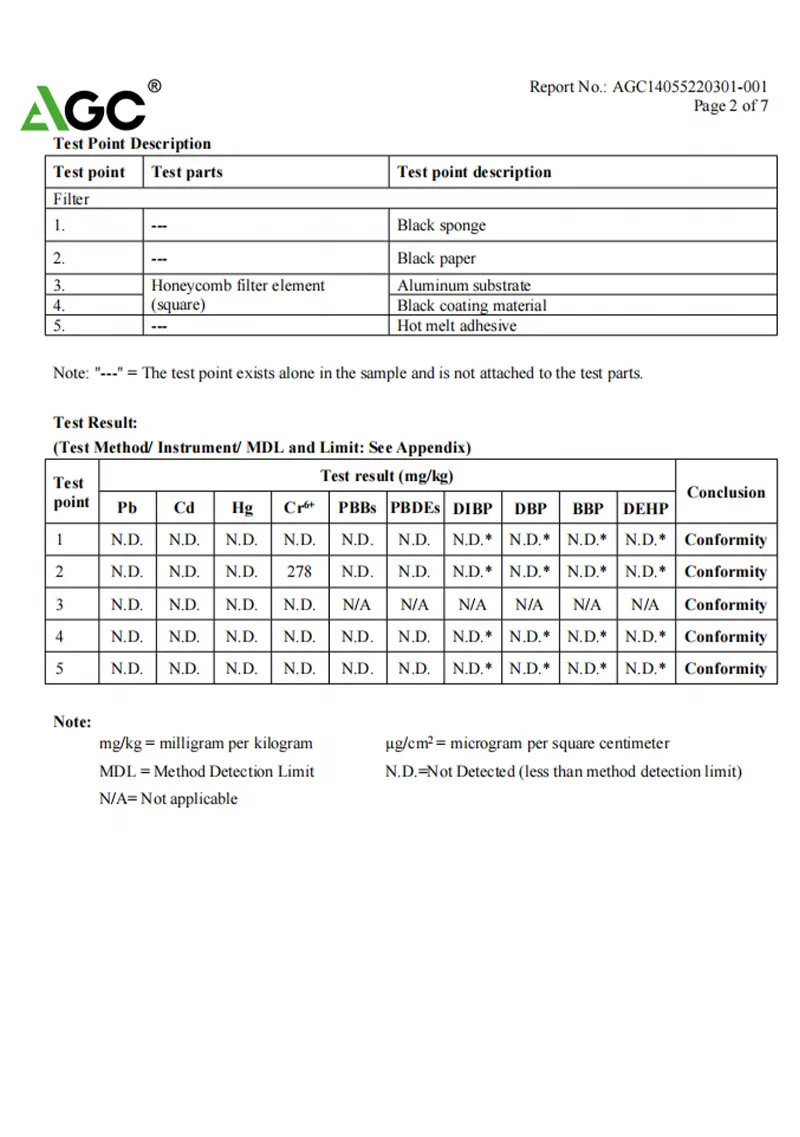

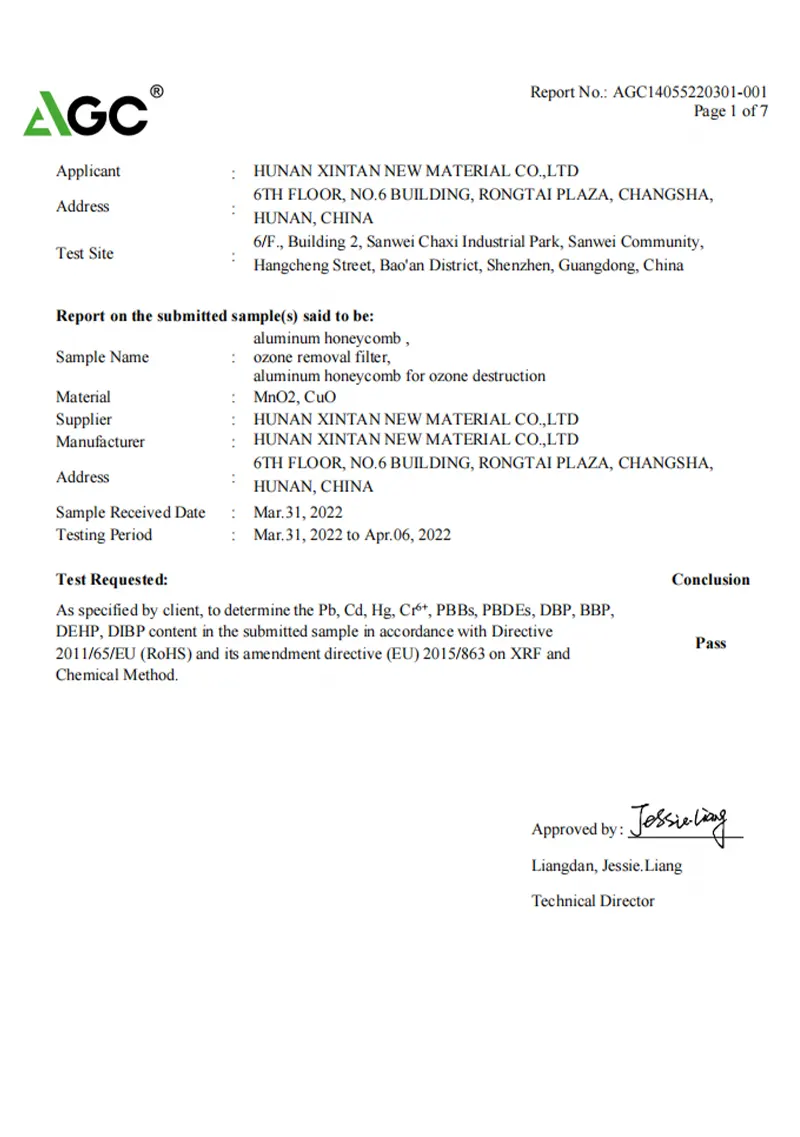

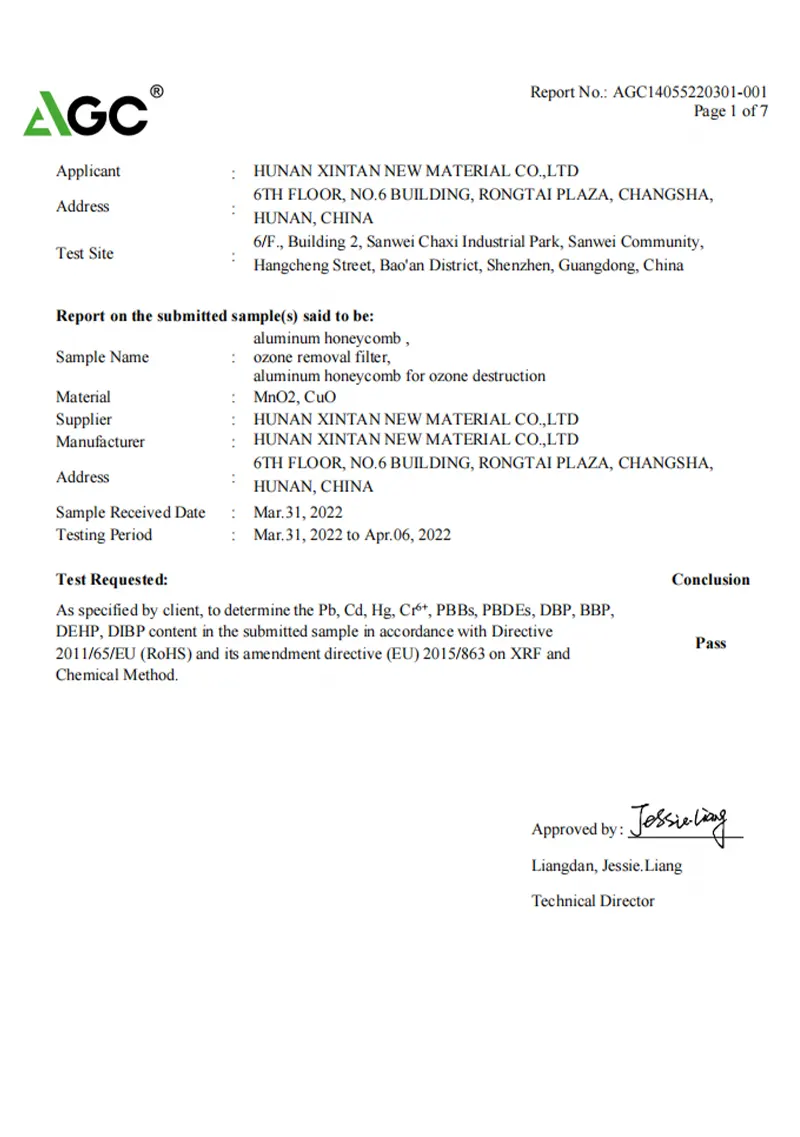

AGC

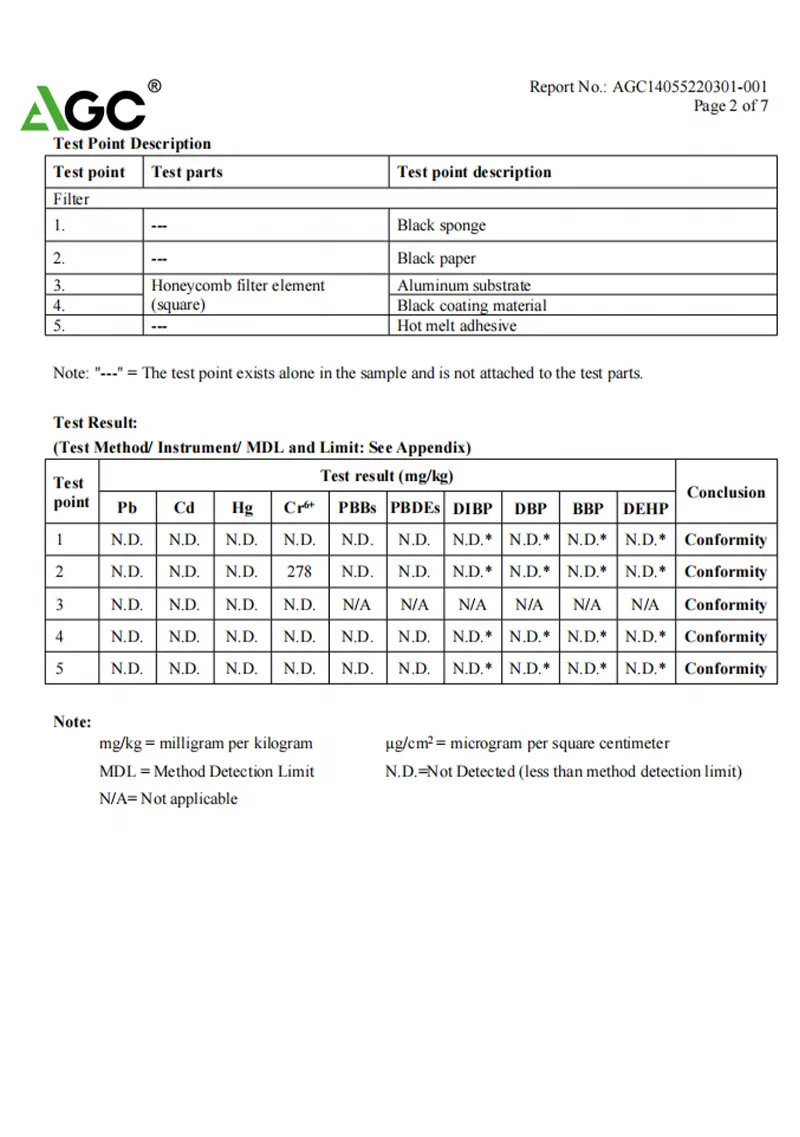

AGC

Related Products

Product Details

Qualification Certificate

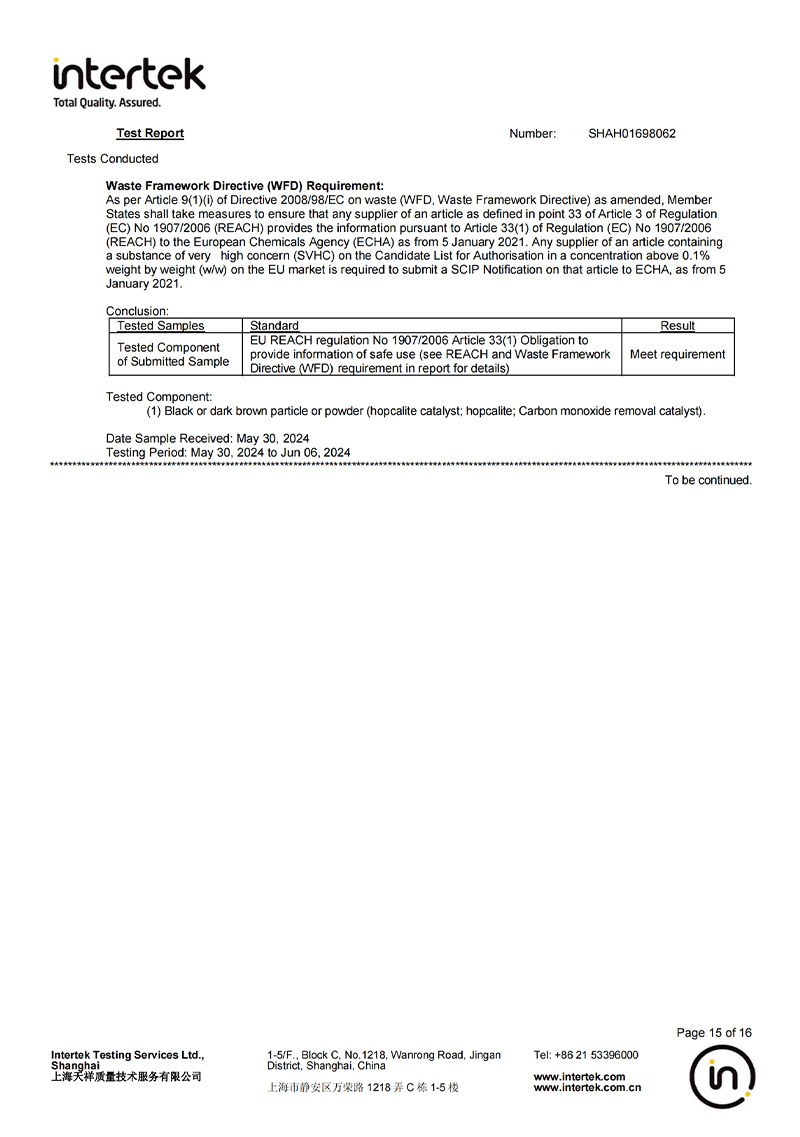

Test Report

Quality Management System Certificate

SGS

SGS

AGC

AGC

Related Products